-

tel: +86 21 5299 9232

-

email: inquiry@rsid-solutions.com

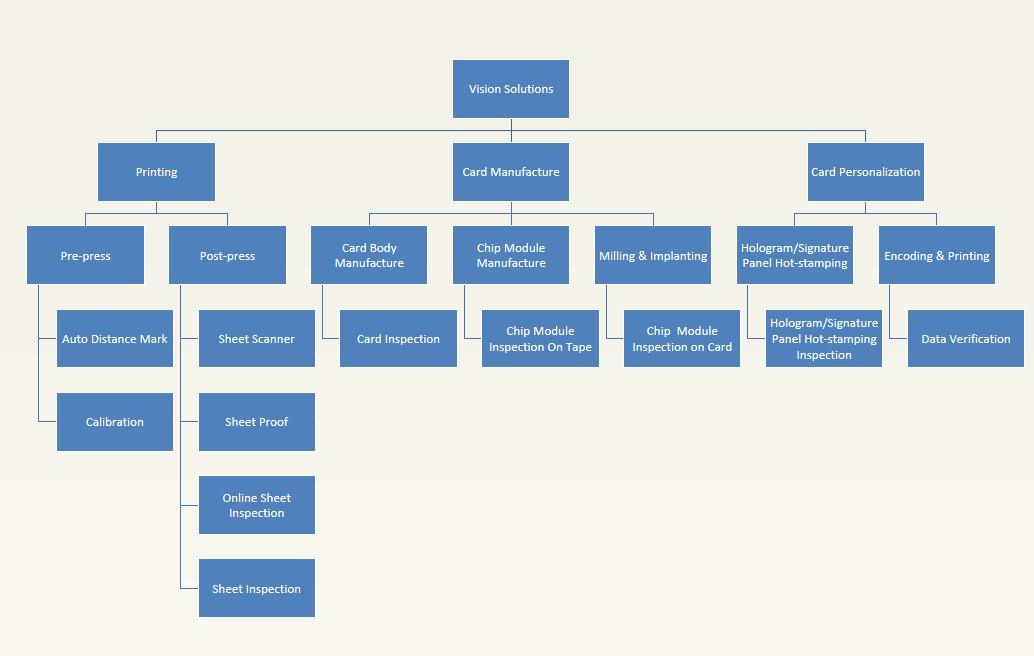

Turnkey Vision Inspection Solutions in Plastic Card Production

Nov 29, 2022

WE ARE THE PROFESSIONAL

- •“China Banknote Printing & Minting Corporation”, in short CBPM-KEXIN.

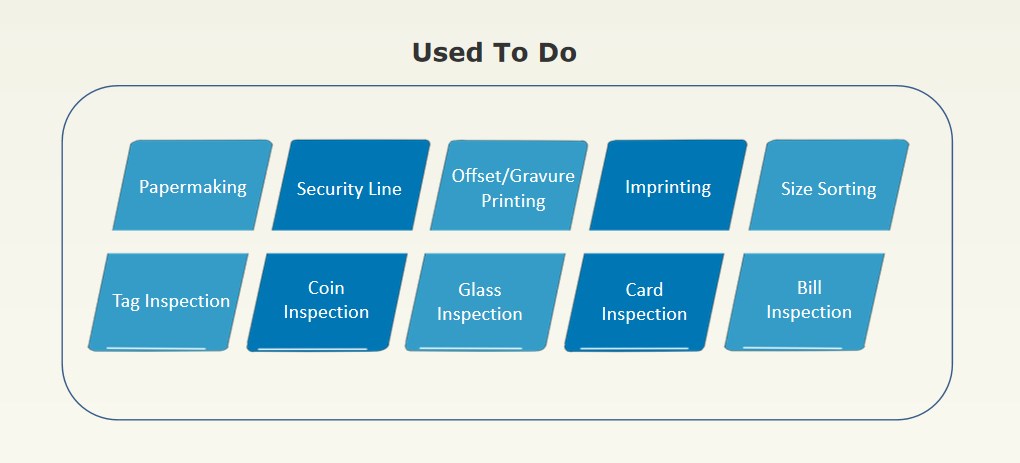

- •Specialized R&D of visual inspection system and solutions for Banknote Printing, Minting and Plastic Cards.

- •Leading player in China which is under the supervision of People's Bank of China.

RSID Solutions with his professional experience serving the Smart Card Industry is ready for this new mission and will continue to provide comprehensive services to customers and global Partners! View www.RSID-Solutions.com for more details.

R&D TEAM BACKGROUND

OUR SOLUTIONS

In 10 years of practice, we found that if optimize the visual inspection algorithm, it can not only avoid fatal flaws, but also save 8 to 10 labors. Even at breakeven, the return on investment is 80% - 90%. A year later, even if the current sales volume is maintained, the annual gross profit growth will be more than the investment itself.

All our vision inspection solutions use this algorithm and are widely used in all key processes of smart card production. Looking forward to sharing more classic case stories with you.

Then:

Pt=X/(10*Y)

ROI=X/10*(10-Pt)/X*100%

Actually after Pt,

Labor Costs Fixed Costs Variable Costs

Q1(New BET) < Q(Old BET); S:New Profit Area

Some defect need to be debugged for a long time , although it can be detected eventually, it caused wrong result, make good card to NG. It means, it will cost a lot about good rate.

Then we get the perfect features of defect that do not involve other noise!!!!!

WE OFFER THE BEST SERVICES

Excellent Users Reference

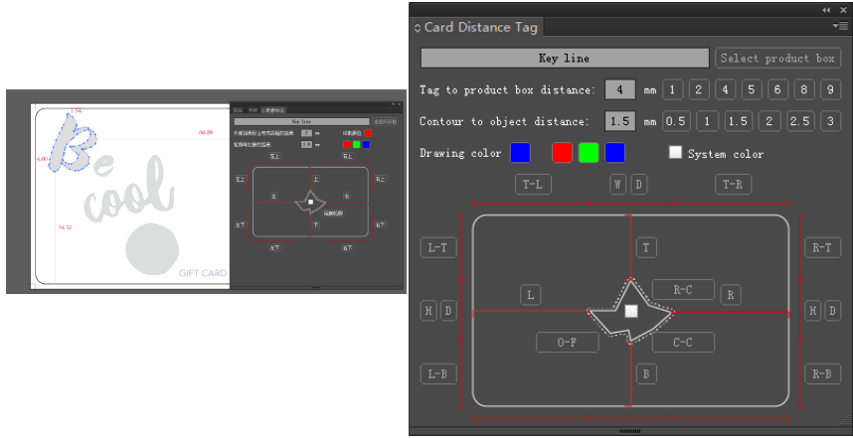

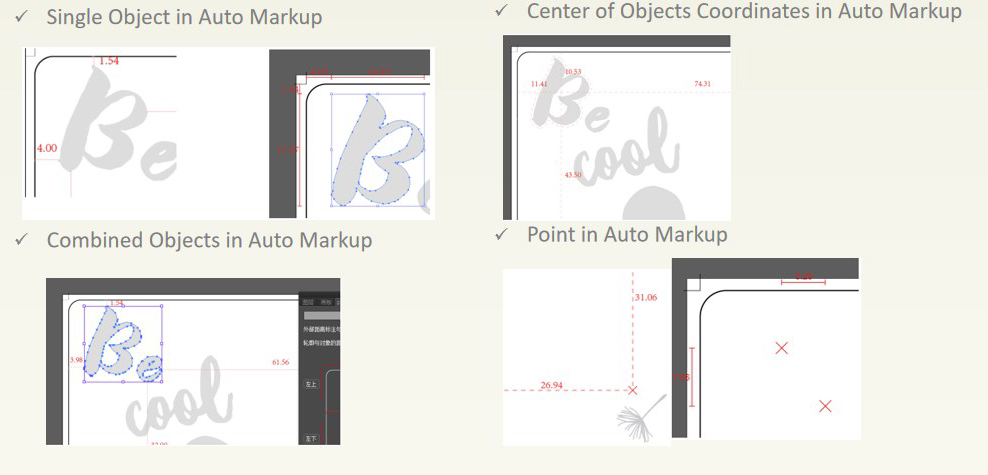

AI Plugin-Automatic Markup

Why Do You Need It

- •Standardize the pre-press markup to be accurate, manageable and traceable

- •More accurate calibration of coordinate extreme value with non- rectangular pattern

- •More accurate distance calculation automatically based on the card outline

- •Auto pattern outline drawing helps to distinguish different process objects.

AI Version Support

- •CS6, CC2017, CC2018

Reference

AI Plugin-Automatic Markup

Reference

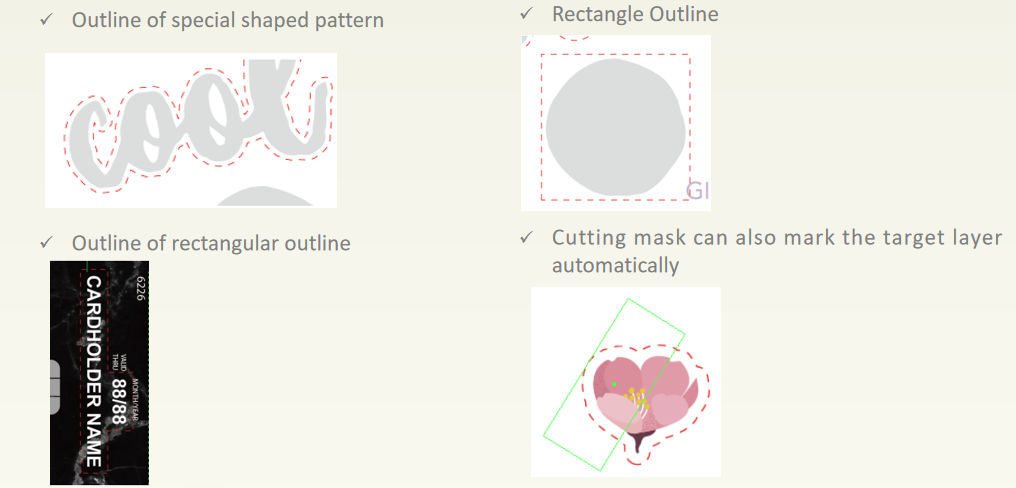

Prepress Calibration Software

Why Do You Need It

- •Eliminate printing accident from source

- •Reduce workload

- •More manageable and traceable

- •Support AI, PDF, JPG, PNG, BMP from 300dpi to 2400dpi

Workflow

Reference

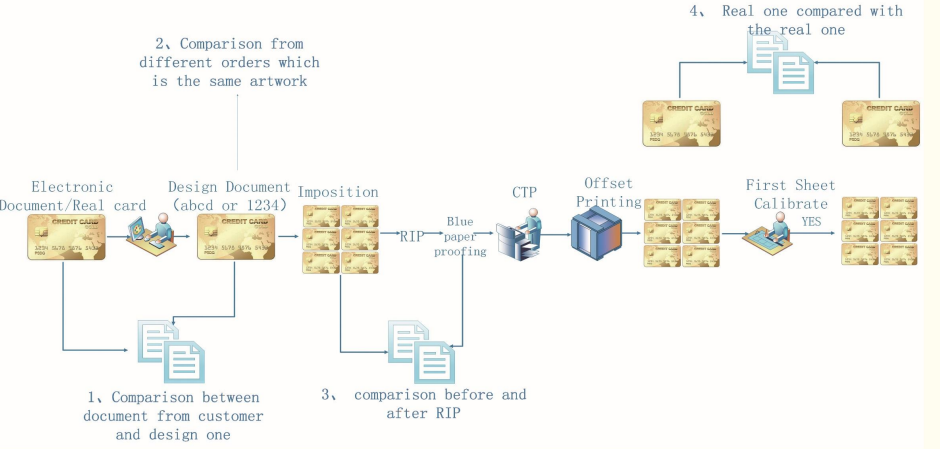

Sheet Scanner

Why Do You Need It

- •Lightweight, convenient, high efficient, desktop sheet scanner

- •Support text and pattern proof between golden sample, draft, and artwork.

Inspection Items

- •Inspect subtle defects

- •Control printing quality of multispectral ink

- •Measure size and location of overprint, gauge and paper

| Technical Category | Index Parameters |

| Max. Inspection Speed | 30s/pc(200dpi), 50s/pc(300dpi), 150s(600dpi) |

| Modeling Time | <5mins |

| Max. Inspection Size | 940*610 |

| Min. Inspection Size | 200*100mm |

| Modeling Type | Original design draft form(AI, PDF, JPG) |

| Camera Resolution | 1000dpi |

| High Contrast Flaw Detection | >0.2mm*0.2mm(like dirty dot, ink dot) |

| Low Contrast Flaw Detection | >0.3mm*0.3mm(like light print) |

| Missing element Detection | 0.2mm*0.2mm |

| Element Error Detection | 0.2mm*0.2mm |

| Noise | <100DB |

Reference

Sheet Proof Machine

Why Do You Need It

- •Save sheet proof staff. One sheet proof machine can monitor multiple printers

- •The real-time sampling inspection during production will generate a professional survey report which provide quantized assessment to manage production.

Inspection Items

- •Light, missing printing area on general region

- •Flood, spot on general region

- •Flood, spot on special region

- •Offset printing register mark

- •Poor Registration

- •Shade

- •Folded corner, strike-through, reverse and half prints

| Defect | Corresponding Inspection Tolerance |

| Light, missing printing area on general region | ≥0.1mm x 0.1mm |

| Flood, spot on general region | ≥0.15mm x 0.15mm |

| Flood, spot on special region | ≥0.1mm x 0.1mm |

| Offset printing register mark | ≥0.2mm |

| Poor Registration | ≥0.1mm |

| Shade | ≥6NBS |

| Folded corner, strike-through, reverse and half plants | >0.2mm*0.2mm(like dirty dot, ink dot) |

| Max. Inspection Size | 600mm*600mm |

| Imaging Resolution | 0.025mm |

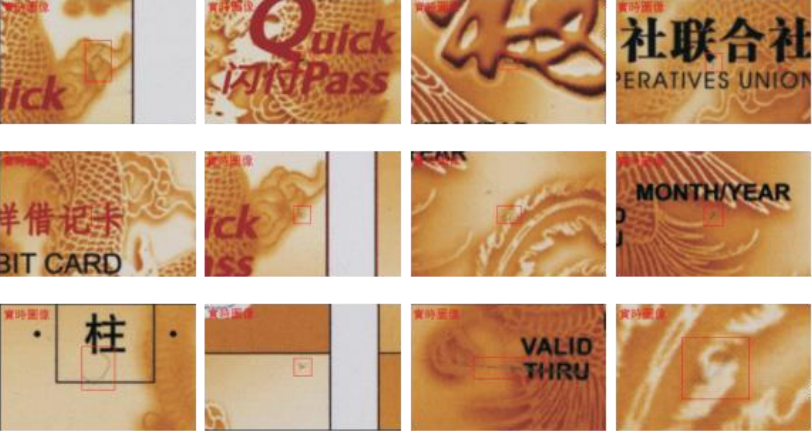

Reference

Online Inspection Module/Auto Sheet Visual Inspection System

Why Do You Need It

- •Quality control for outsourced printed sheets

- •Save inlay, chips and hologram wasted by printing issue in next processes

- •Adjustable tolerable defective notes allow to accept sheets which only have few light defective cards flexibility

- •Available to integrated on offset printer or our own platform

Inspection Items

- •Layout Error

- •Bad Registration Printing

- •Printing Error, Missing, Ink Cracking

- •Chromatography, Chromatic Aberration Fiber, Scratches, Dirty, Finger Print…

- •Pearly finish, Transparent Sheet (Optional)

| Model | RD-GS001 |

| Output | 1,900UPH above |

| Max. Inspection Width | 500mm (can be customized) |

| Cards Feeding Capacity | More than 2,000 sheets(0.15mm thickness) |

| Support | Offset printing PVC/PET/ABS/PC sheet |

| Optical System | 8192 Pixel Color Dalsa Line Array Cameras |

| Landscape | 540mm |

| General Defects Inspection Tolerance | 0.067mm² (Contrast<20 Grayscale) |

| Special Defects Inspection Tolerance | 0.25mm² (Contrast>10 Grayscale) |

| Size Inspection Tolerance | 0.26mm*0.26mm (There must be a mark point in the field of view) |

| Optional | Pearly finish, transparent sheet |

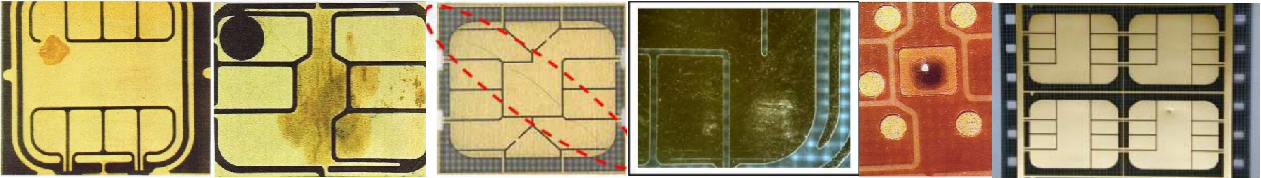

Card Surface Inspection System

Why Do You Need It

- •8-10 labors saving

- •Avoid fatal flaws on card

- •Improve quality and increase competitiveness

Inspection Items

- •Surface Quality: Scratch, Spot, lamination scratch, Bubble, Bulge, Dent, Punching Error, Fiber…

- •Printing Quality:Color Registration, Registration Error, Incomplete Text, Ink Spots …

- •Card Visual Items: Shape & Position of S.P, Magnetic Stripe, Hologram…

- •Optional: UV Invisible, Hologram Content, Pearl Finishes, Pit, IR Print, Transparent Windows ...

Compare with Others

| Item | Europe | Other Domestic Brand | RSID Solutions |

| Social Card | OK | OK | OK |

| GSM Card | OK | OK but limited capacity | OK |

| Banking Card | OK | NG | OK |

| Software | Complicated | Simple | Easy for operation |

| Template Setting | Over 1 hour | 1-2 hours or NA | In 30mins |

| Punching Error, Burr, Pearly Finish, Lamination Scratch, Film Broken or Fold, Pit on bright side, Ghosting, IR printing, Transparent Window, | Bad or NG | NG | Optional |

| Price | Expensive | Cheap | Affordable and Reasonable |

| Service | Expensive | Poor or NA | Strong Team and Local Service |

| Manual Checking | Generally no | Needed | No |

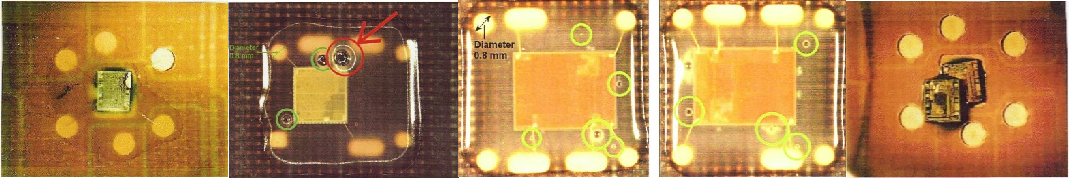

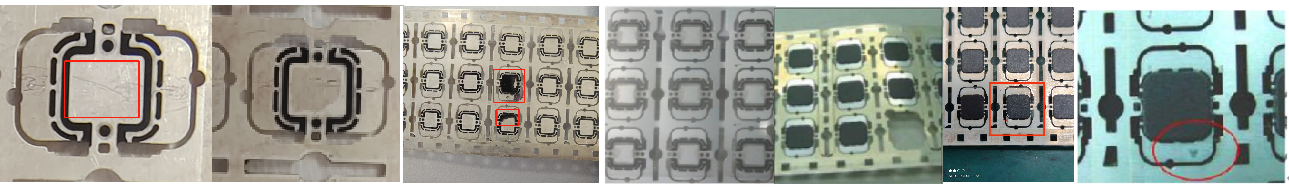

AOI Smart Card Module Tape

Throughput is 30~32kUPH, Available for 6pin, 8pin and MOA4 tape

Inspection Items

Contact Chip Module:

- •Dirty, scratch, Bubbles, Hole print...

- •Die missing, multiple dies, Contacts missing, lead interference, contact disconnected...

- •Broken lead, glue area unmatch, incomplete encapsulation...

Contactless Chip Module:

- •Scratch, stain, metal surface overflow, module missing...

- •Incomplete encapsulation, bright spots...

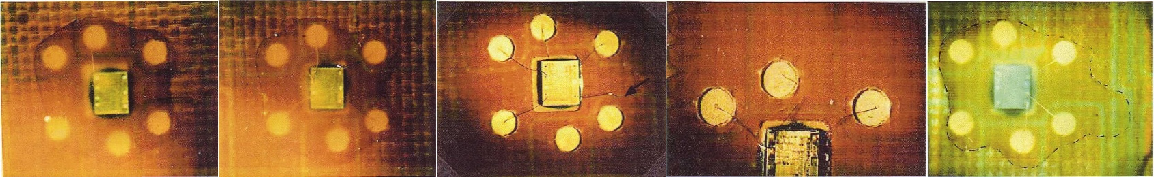

Chip Implanting Inspection Module 1

Why Do You Need It

- •Avoid continuous unqualified chip implanting

- •Eliminate unqualified products, improve the efficiency for the next process and reduce the production quality risk

- •Get the real-time health status of the equipment and the quality of consumable and indirectly improve the machine maintenance efficiency and consumable quality by analyzing the precise data of qualified rate

- •Provide operator assessment data and reduce the work intensity and pressure of the boot staff

Hologram & Signature Panel Inspection Module 2

Why Do You Need It

- •Avoid the continuous defects

- •Reject unqualified hologram and signature panels and improve the production efficiency

- •Signature panel is dynamic which needs unique inspection and One operator can control two machines.

- •End user will get the machine health condition and consumable quality and it’ll improve machine maintenance efficiency and consumable quality by calculating precise quality rate

- •Reduce quality risk, power and pressure of the operator and management cost

Inspection Items

-

Dirty

-

Damage

-

Surface Anomaly

-

Super-wide

-

Multiple Printing & Damage

-

Dirty

-

Signature Panel Missing

-

Damage

-

Narrow

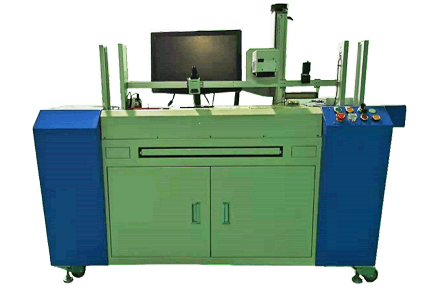

Variable Data Verification System

It's a standalone platform which equipped with 10 workstations, such as LF/HF/UHF readers, lasers, code scanning guns or OCR, drilling etc.

Why Do You Need It

- •Read and detect UID, sector, module and password.

- •Card encoding, encryption, UID conversion.

- •Optional laser engraving, variable data verification, drilling.

Variable Data Verification System

| Model | RD-TD01 |

| Throughput | 10000-15000pcs/h |

| Card Dimension | CR80 ISO standard (Customizable) |

| Dimension (mm) | 1450(L)×550(W)×1350(H) |

| Power | 650W |

| Air Pressure | 5 bar≤P≤7 bar |

| Weight | 185 Kg |

| Power Supply | AC220V 50Hz |

| Supported Chip Type | LF:4100/4305/5577; HF:ISO14443-A/B/C Contact, Contactless including CPU card; UHF:ISO18000-6B/6C |

| Drilling (Optional) Tolerance | +/0.1mm |

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Jun 26, 2025

Functions of T8200Pro-G

Mar 13, 2025

Telecom Card Personalized Solution

Jan 17, 2025

PT300 Series Reader and Tester Introduction

Oct 28, 2024

Smart Card IC Packaging Solution