-

tel: +86 21 5299 9232

-

email: inquiry@rsid-solutions.com

Smart Card IC Packaging Solution

Oct 28, 2024

What Can We Do?

*5in1 Solution: IMS, Production Line, Tools&Instruments, Material and Service.

Intelligent Manufacturing System: Managing the whole factory in a digital, intelligent way.

Differenet Level of Production Line: high level and low cost of configurations for different requirements.

Complete Supply Chain: most cost-efficiency of tools&instruments and material supplying which covers all need by production.

Project Management: ICP Packaging Factory Builing Project Management.

Local Service: On site installation, maintenance, accompanying production, and training services for the entire production line.

Consulting Service: The international expert team provides professional factory building consulting services.

IC Packaging Processing

Smart Card IC Module Types

Contact Module Type

Dual-Interface Module Type

New Type of Contactless Module Type

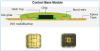

Cross Section of Contact/Dual-interface Module

Material

● Substrate Tape:

- Glass epoxy with 1 side or 2 sides metal layers (1 side metal layer for CB module and 2 sides metal layer for DIF module).

- Gold or Palladium plating on surface of contact side metal layer.

- Total thickness of tape: ~ 165μm

● Epoxy glue for chip attachment.

● Bond wire: Au Ø 24 μm(20-24 μm)

● Glob Top: epoxy glue

● Chip size :~max 3.5x3.5 mm with 150 μm thickness (chip thickness depending on final module design needed)

Module development possibility on WB Platform

Wire Bonding platform is easily used to produce 3 major types of module package applied for smart card market: Contact Base, Dual Interface and Contactless.

● CB/DIF: Normally epoxy glass base substrate is used for CB(contactless base)/DIF(Dual Interface) module assembly from design perspective.

● CTL: Both metal lead frame and epoxy glass base substrate may be selected for pure CTL(contactless) module assembly

● There is constrain to develop ultra-thin and small size module on WB platform.

Processing Procedure

Contact/Dual-Interface IC Packaging Production Line

● Average Throughput: 22,000UPH

● Considering Factors:

- Mass production and More easier to enlarge capacity.

- Machine Backup to avoid production stop

● Configuration Extention: More standalone machines can be flexibly added into production line to get higher capacity after the whole production line has been controlled well and under good status.

High Throughput

● Flexible machines quantity for high throughput: DB and WB have maximized the throughput of CME, CMT, and AOI by increasing the number of machines, enabling the entire production line to maintain extremely high throughput.

● Part of production line running for high throughput: The standalone type machine production line, by setting up a buffer zone, has sufficient materials to be produced for each machine, which can keep the entire production line in high-speed production at all times.

High Flexibility

● Capacity Balance: The balance among different production speed for different machines is possible and much more easier.

● Mix Orders: Different Orders such as different requirement for different contact modules or contact/dual-interface mix production could be executed at the same time.

● Anti-breakdown: The production will not be affected by one or part of machines’ breakdown.

● Easier Maitenance: The standalone type machine is simpler and more flexible in the production process, troubleshooting and handling as well as production line maintenance are more simple.

High Extensibility

● One machine more instead of the whole line: A certain machine can be added into production line seperately on the need of some orders someday. No need to purchase another whole production line.

● Low cost for High Throughput: Higher Configuration such as more tester and contact/dual interface/pure contactless tester can be equipped into the same production line so that more products or higher throughput is available in a very low cost.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Jun 26, 2025

Functions of T8200Pro-G

Mar 13, 2025

Telecom Card Personalized Solution

Jan 17, 2025

PT300 Series Reader and Tester Introduction