-

tel: +86 21 5299 9232

-

email: inquiry@rsid-solutions.com

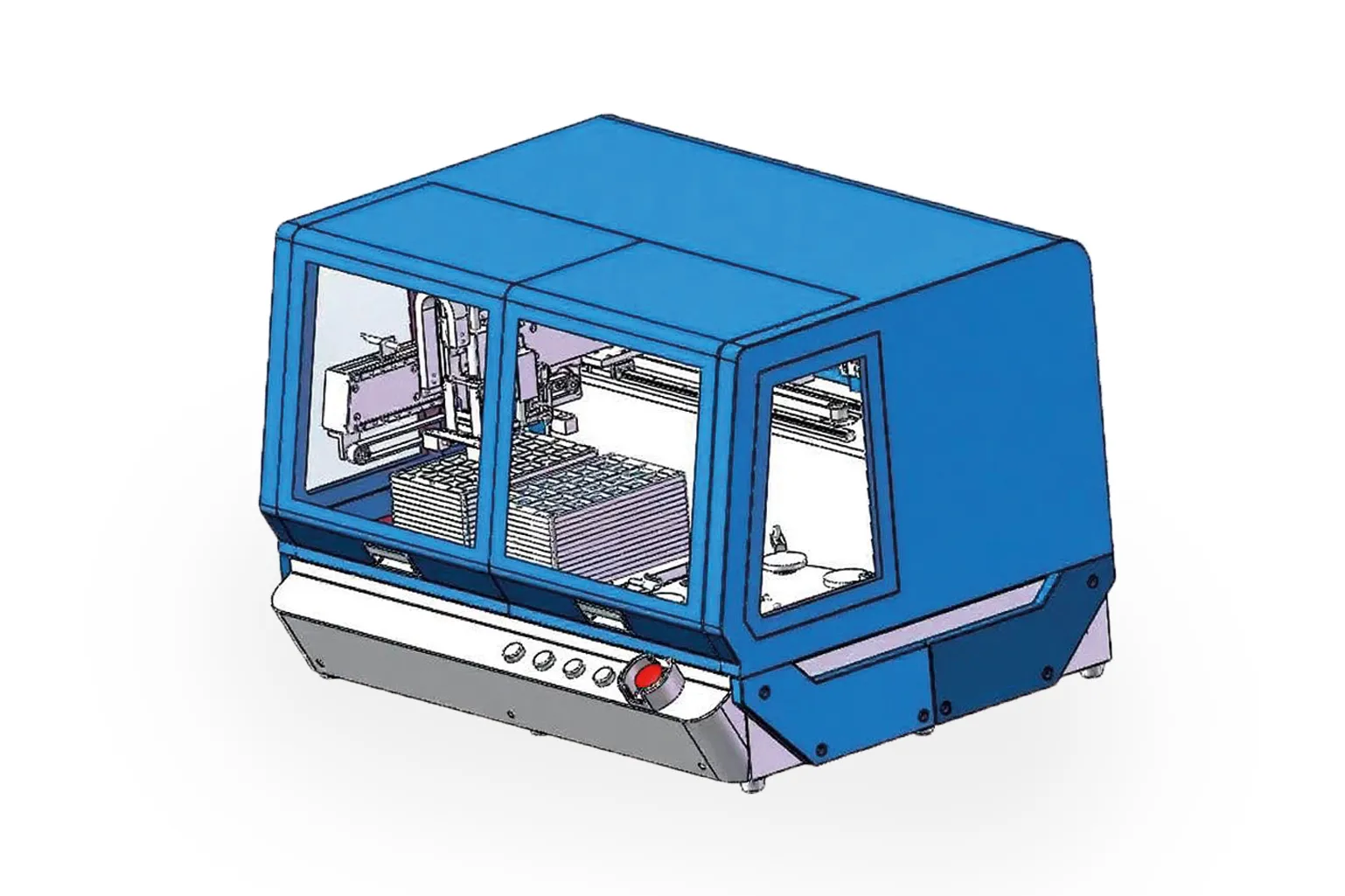

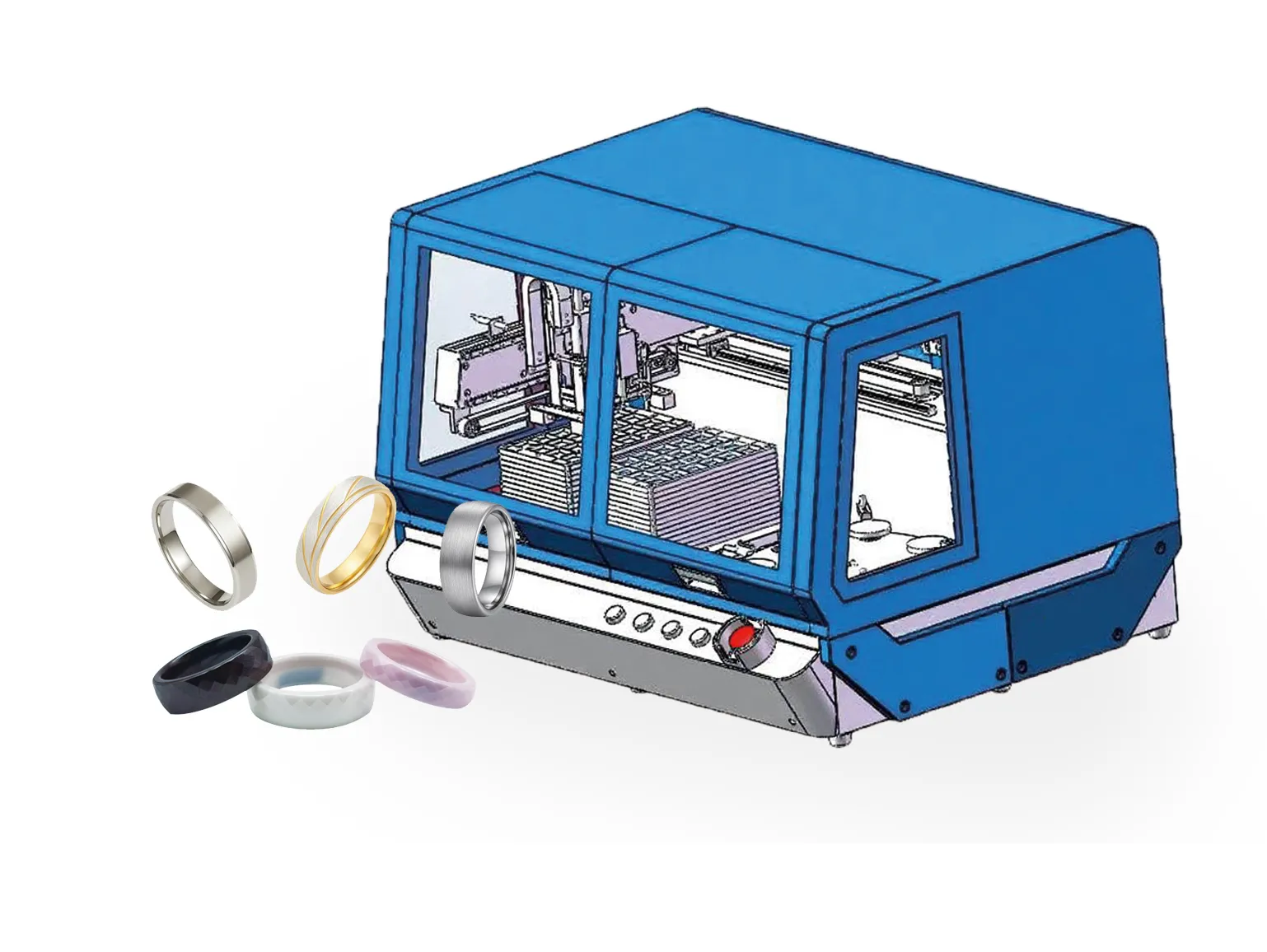

A multi-functional automatic testing and Perso machine for Contactless Rings of HF(NFC) or LF, can be used for different sized Rings assembly of online inspection, testing and personalization. It’s ideal tools for RFID Ring assembly maker and also Initialization (Pre-perso), Personalization. Contactless Rings can be widely used for contactless payment (Tap & Go) and non-payment applications like social connection, e-promotion, business card, credential and membership etc. This machine is specially designed for RFID Ring manufacturer and Personalization bureau.

FUNCTIONS

Production Inspection

· Measure and check the read range of RFID rings

· Chip UID or ATS read and data collection

· RF performance likes Frequency, Q-factor Inspection (optional)

· Visual inspection (OCR optional)

Chip data/script encoding

· RFID Chip Support

- HF/NFC: micro-processor chips like Infineon Secora Pay Connect, logical encryption chips in ISO14443A likes NTag family, Mifare family, ISO15693 Icode family.

- LF: ATA5577 (Optional)

· Read/encode time: 40-50s (depends on chip)

· Software

- Production Test mode

- Personalization mode (likes card issuance)

- Test data recording

· Laser marking

- Images and character’s engraving

- Variable data engraving

Test data recording

Customizable development available

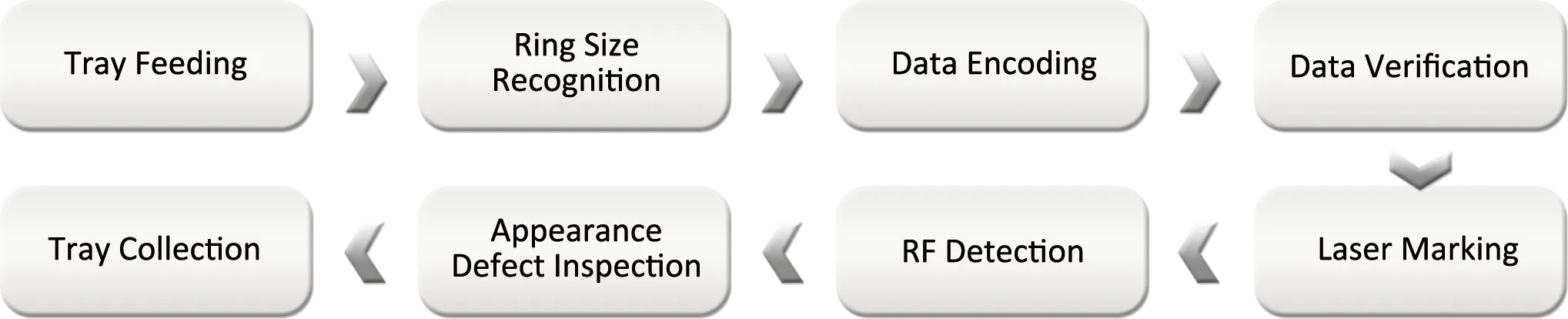

WORKFLOW

CONFIGURATION

Tray Platform

· Supports tray receiving and feeding modes, with at least 25 rings per tray.

· Simultaneous feeding of up to 10 trays.

· Supplied with 10 sets of trays.

Robotic Arm

· Equipped with 1 gripper to transport rings from the feeding unit to the rotating turntable.

Waste Bin

· Defective rings are sent through the waste chute to the waste drawer for unified handling.

· An optional waste card box with classification function can be configured, enabling multi-type waste sorting and recycling.

Turntable

· 6 working stations for ring rotation OCR Recognition (Optional)

· Inspect surface defects on the rings.

Encoding

· Used to read and encode for rings.

· Test read/encode distances

Size Recognition

· Used to detect inner diameter on the rings.

Laser Marking (Optional)

· 1 fiber laser machine

· Laser holder angle is adjustable.

Verification

· Test ATS and Q-factor of the rings.

· Resonant Frequency Measurement

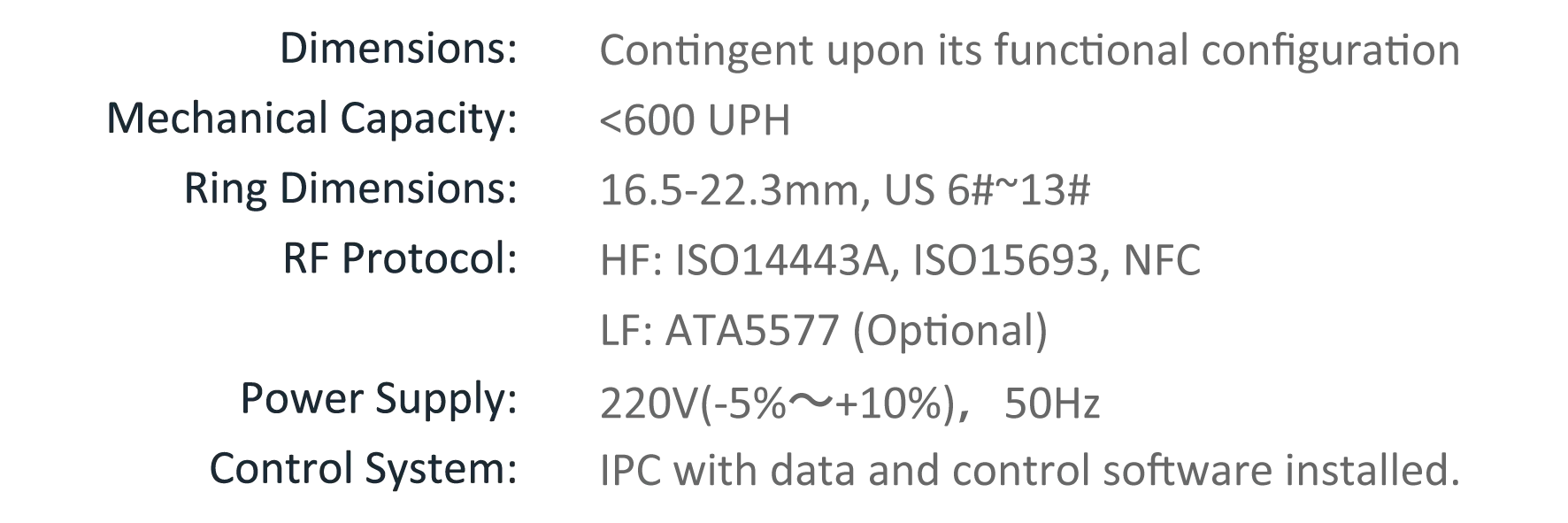

SPECIFICATION

FUNCTIONS

Production Inspection

· Measure and check the read range of RFID rings

· Chip UID or ATS read and data collection

· RF performance likes Frequency, Q-factor Inspection (optional)

· Visual inspection (OCR optional)

Chip data/script encoding

· RFID Chip Support

- HF/NFC: micro-processor chips like Infineon Secora Pay Connect, logical encryption chips in ISO14443A likes NTag family, Mifare family, ISO15693 Icode family.

- LF: ATA5577 (Optional)

· Read/encode time: 40-50s (depends on chip)

· Software

- Production Test mode

- Personalization mode (likes card issuance)

- Test data recording

· Laser marking

- Images and character’s engraving

- Variable data engraving

Test data recording

Customizable development available