-

tel: +86 21 5299 9232

-

email: inquiry@rsid-solutions.com

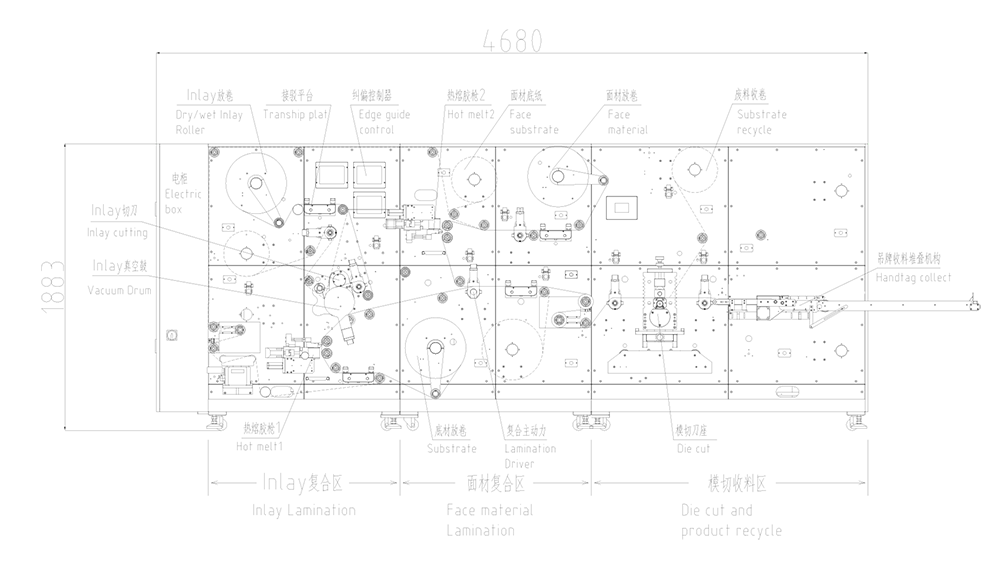

RFID Label Automatic Lamination Machine RFCL-822-RX

Presentation:Flexible,Fast and Modular Automatic Converting Solution

Advantage:Highest Level of Customization,Highest Application Flexibility,Easy Product Charge Over

Application:Smart Labels and Smart Tickets from reel-to-reel or from reel-to-ticket

OVERVIEW

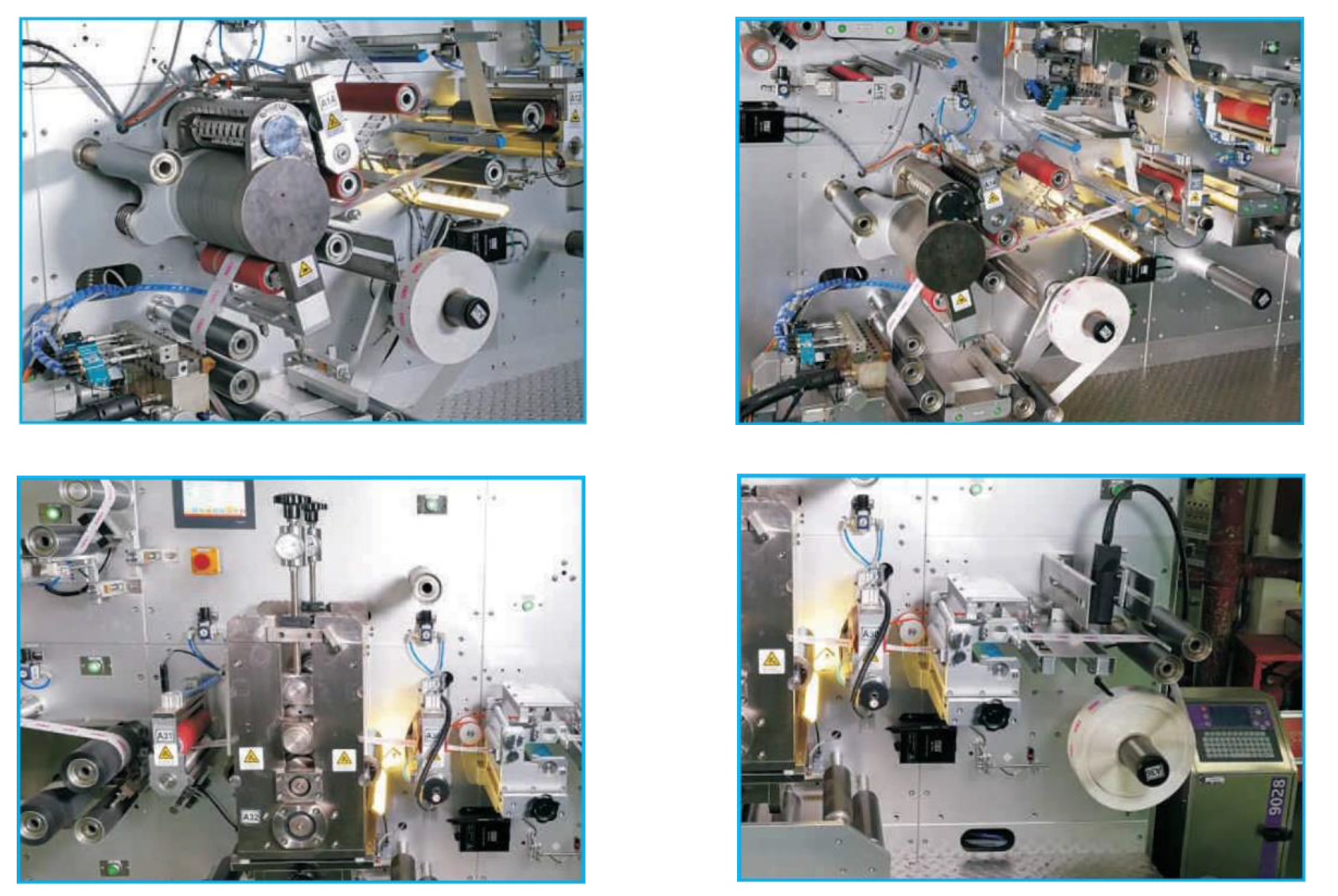

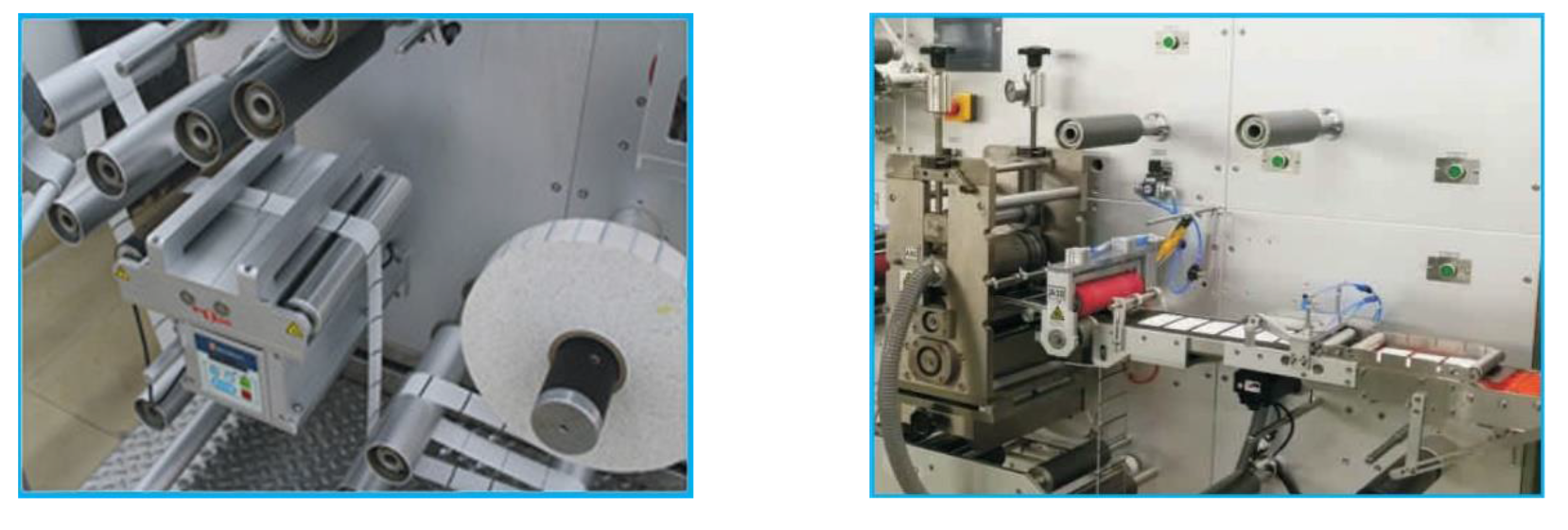

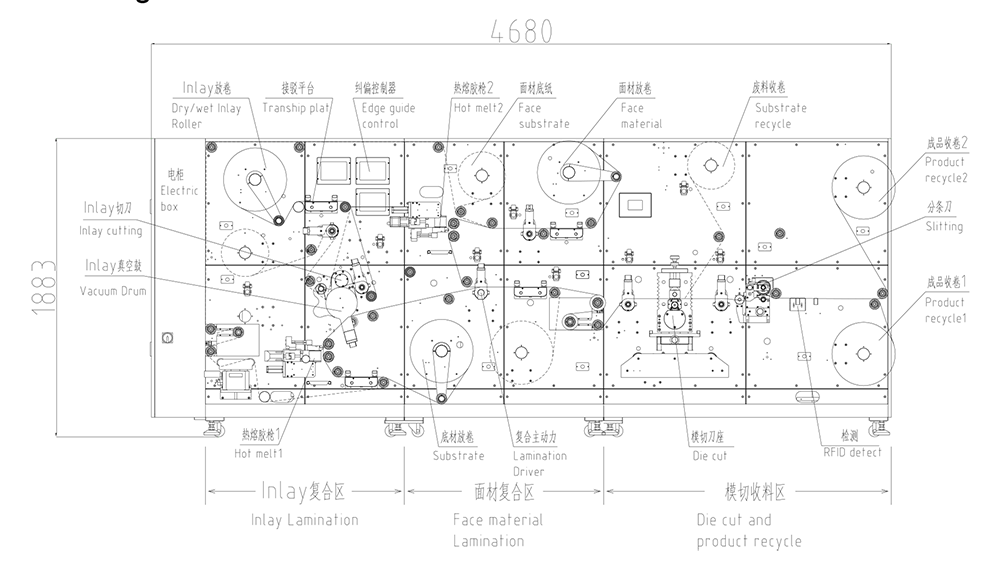

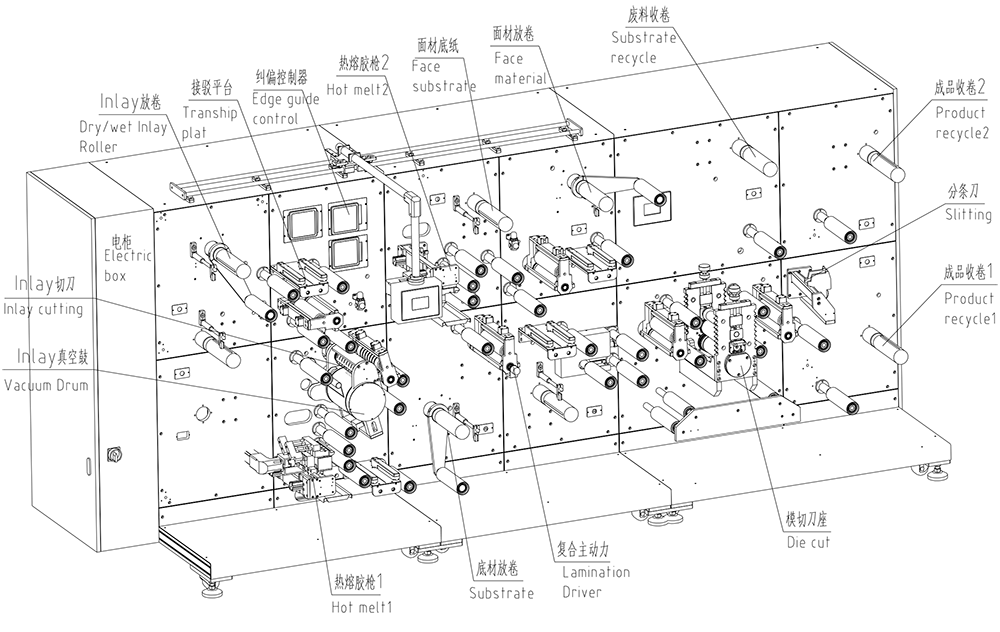

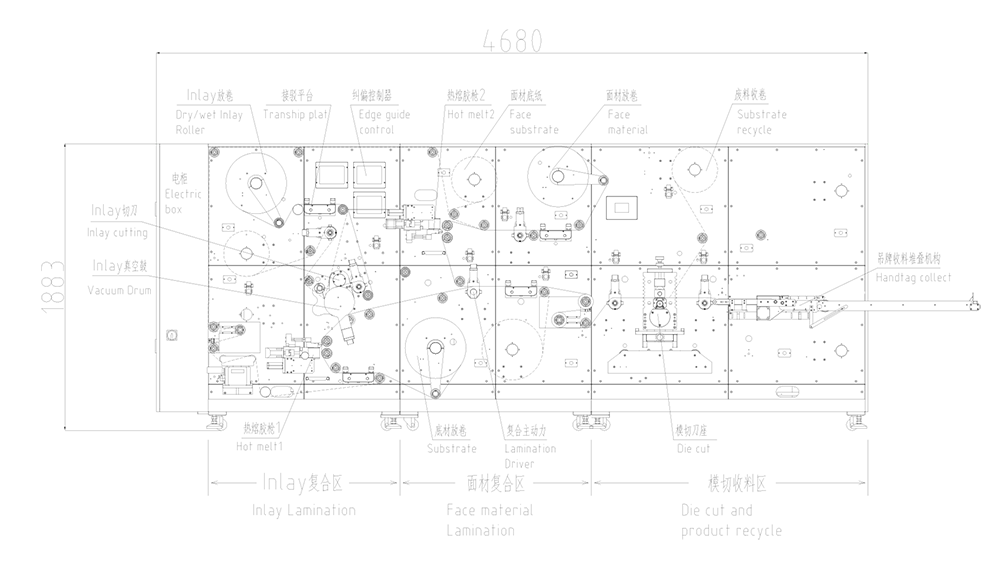

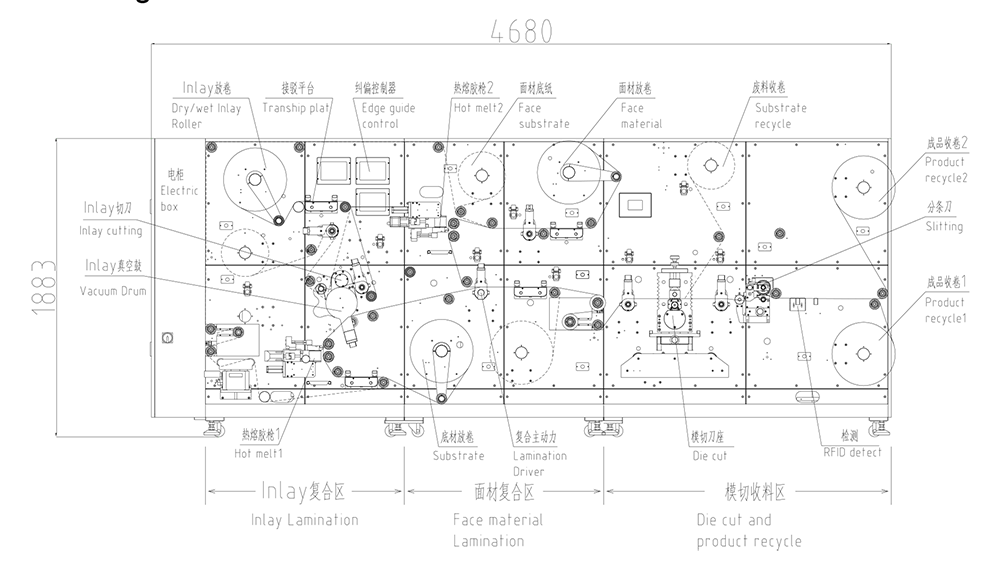

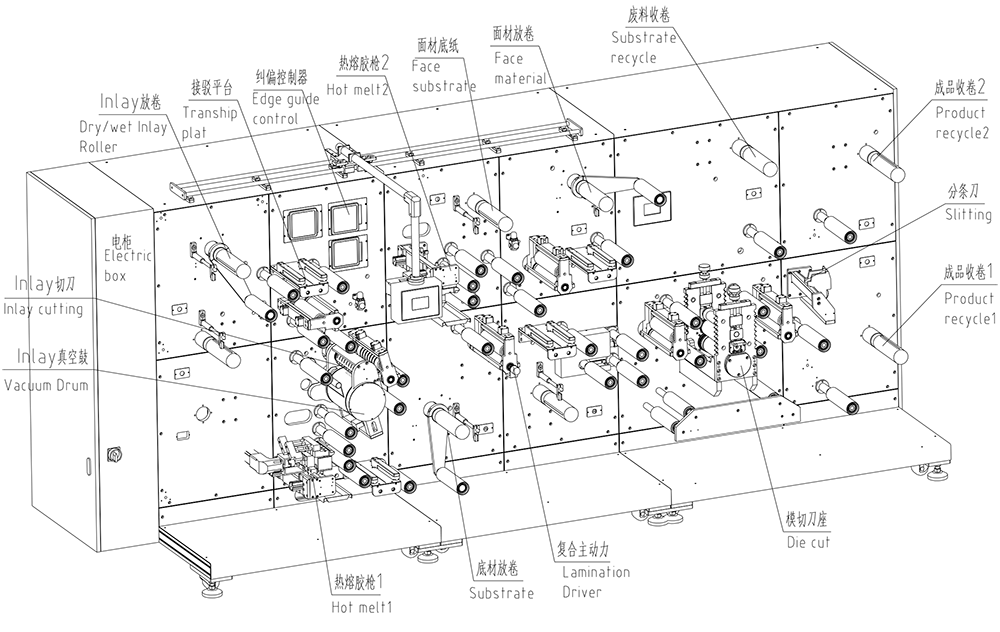

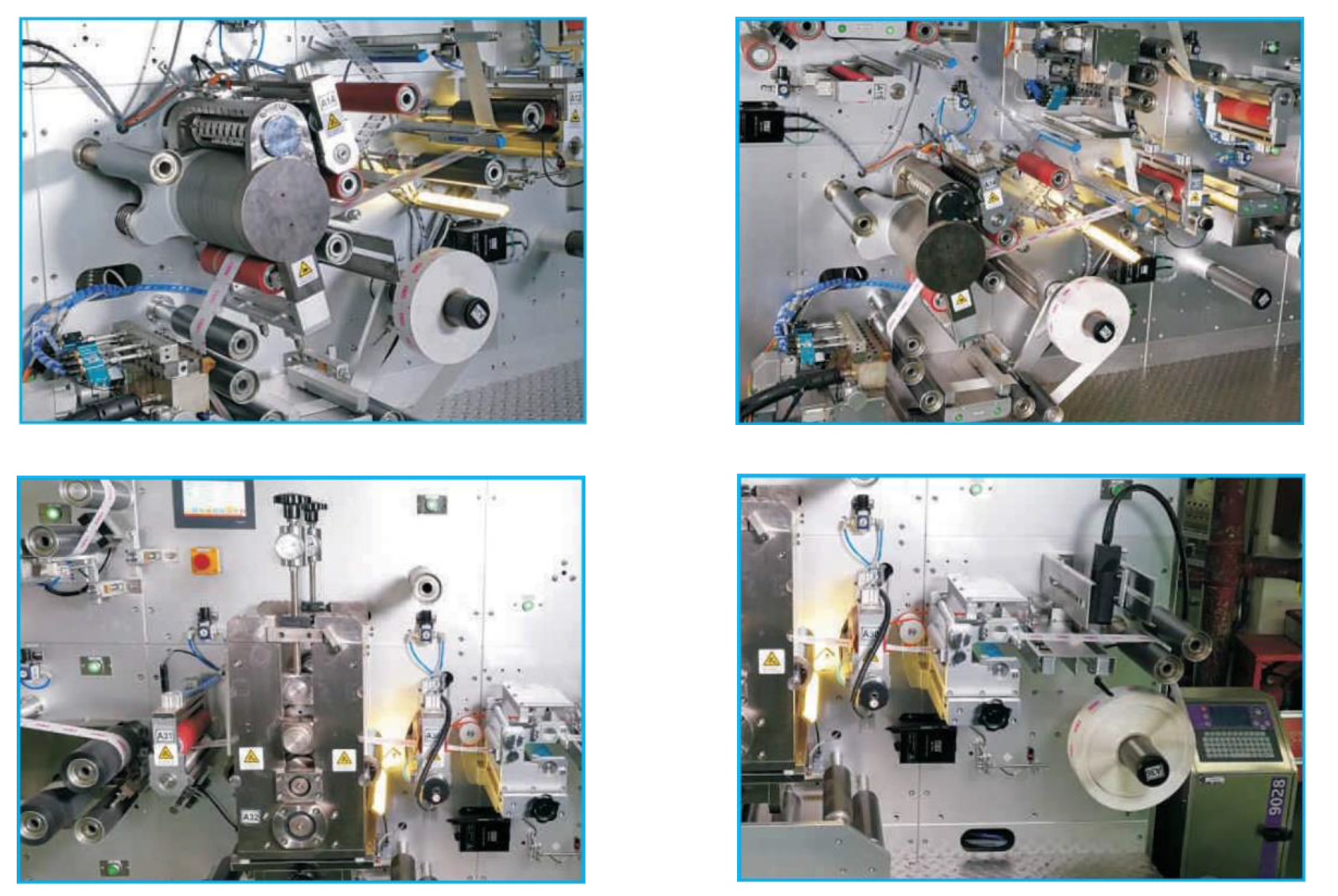

RFCL-822-RX Label Automatic Lamination Machine is integrated with RFID inlay laminating, surface of RFID tag laminating which includes converting of pre die-cutting label and continuous label.

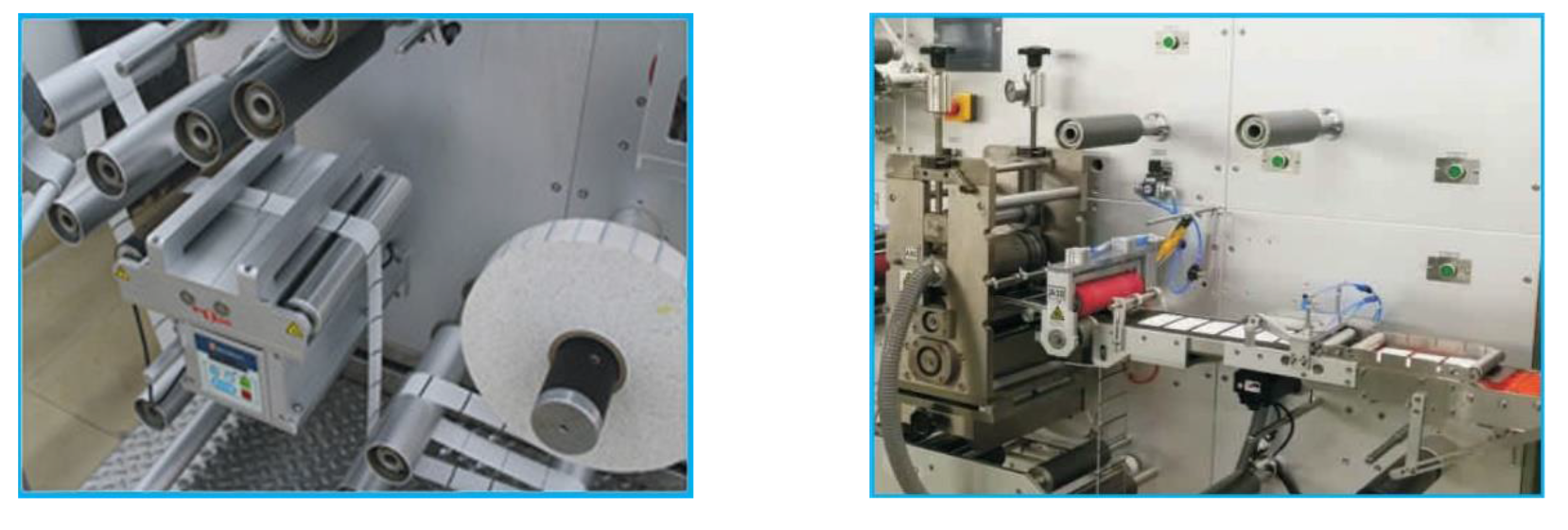

The speed of automatic laminating may reach to 60 meters per min. Assort with the special dry INLAY die-cutting module and hot melt glue mechanism, our machine is able to laminate dry & wet inlay label. Simultaneously if with high speed magnetic roller die-cutting module, we may help to implement the label after the process of die cutting and cards production.

SYSTEM

FEATURES

• Dry inlay/wet inlay applied with inlay positioning cutting and vacuum drum institution. 3 sets high-speed rectify deviation Machine. 13 shaft servo system control.

• The main servo feeder institution.

• The finish paper is pre die-cutting by vacuum drum institution enable to have stabilized labeling.

• The ultromotivity constant tension institution of inlay label.

• The Label unwinding axial deviation to ensure stabilized label transfer.

• Specially install a non-stop lap changing device, making changing roll and paper receiving without stopping the machine become true.

• Automatically speed adjusted to track alignment.

• Lamination accuracy is±0.3mm (Subject to material printing accuracy, normally the general accuracy is in ±0.5mm).

SPARE PARTS

|

ITEM |

DESCRIPTION | QTY | REMARK |

|

RFID Label Automatic Lamination Machine host |

CL-822 |

1 SET | |

|

Hot melt adhesive glue system |

CL-HT-102 (Servo Control) |

1 SET | |

|

Roller die cutting unit |

CL-R21F (Servo Control) |

1 SET | |

|

Conveyor for tag product |

CL-C22 |

1 SET | |

|

RFID Detection system |

UHF/HF testing system |

1 SET | |

|

NOK Inkjet |

Imaje 9028 |

1 SET | Black mark for NG label |

SPECIFICATIONS

|

Production Speed |

• Max.60M/Min(Subject to label material) |

|

Laminate Accuracy |

• ±0.5mm(±0.3mm in condition of High precision material printing) |

|

Label Max. Width |

• 190mm |

|

Label Max. Length |

• 520mm(die-cut length) |

|

Label Max. Thickness |

• Less 300g by single layer |

|

Label Inner Diameter |

• φ76mm |

|

Label External Diameter |

• Max. φ520mm |

|

Function |

• RFID dry/wet Inlay, paper, fabric Laminating. |

|

Machine Size |

• 4410*1600*1950(mm) |

|

Power |

• 3 Phase 380V / 50-60Hz / 18KW |

|

Weight |

• 4000Kg |

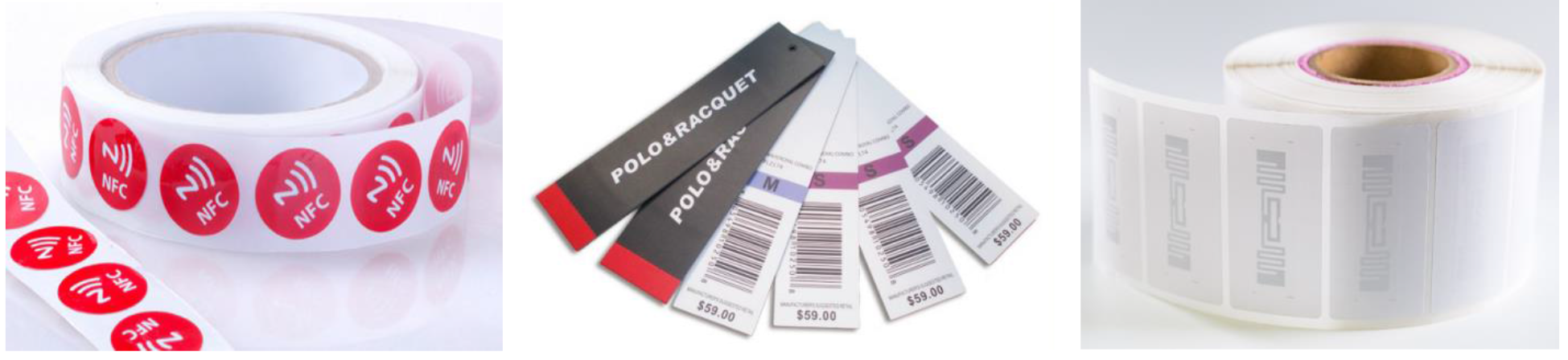

APPLICATION

• Ordinary paper of RFID lamination.

• Hand-tag RFID lamination.

• Care-label RFID lamination.

• Dry inlay & wet inlay lamination.

• Cutting function for dry inlay.

• Finish paper and body paper automatically alignment laminated.

• From the type of silicone oil body paper can be used as body paper.

• Double side adhesive label lamination.

• Standard adhesive label lamination: Label body paper & finish paper split – laminating inlay- Three layers label lamination.

Still under construction. coming soon...

• Dry inlay/wet inlay applied with inlay positioning cutting and vacuum drum institution. 3 sets high-speed rectify deviation Machine. 13 shaft servo system control.

• The main servo feeder institution.

• The finish paper is pre die-cutting by vacuum drum institution enable to have stabilized labeling.

• The ultromotivity constant tension institution of inlay label.

• The Label unwinding axial deviation to ensure stabilized label transfer.

• Specially install a non-stop lap changing device, making changing roll and paper receiving without stopping the machine become true.

• Automatically speed adjusted to track alignment.

• Lamination accuracy is±0.3mm (Subject to material printing accuracy, normally the general accuracy is in ±0.5mm).

|

Production Speed |

• Max.60M/Min(Subject to label material) |

|

Laminate Accuracy |

• ±0.5mm(±0.3mm in condition of High precision material printing) |

|

Label Max. Width |

• 190mm |

|

Label Max. Length |

• 520mm(die-cut length) |

|

Label Max. Thickness |

• Less 300g by single layer |

|

Label Inner Diameter |

• φ76mm |

|

Label External Diameter |

• Max. φ520mm |

|

Function |

• RFID dry/wet Inlay, paper, fabric Laminating. |

|

Machine Size |

• 4410*1600*1950(mm) |

|

Power |

• 3 Phase 380V / 50-60Hz / 18KW |

|

Weight |

• 4000Kg |

Still under construction. coming soon...

Still under construction. coming soon...

Services before Sales

- Reply your inquiry within 24 hours.

- Communication by email.

- Welcome you visiting our factory and final users in China.

- Help for VISA application and Invitation Letter issuing.

- We afford you consultation for 24 hours of 7 days in the process of sale and after service by phone or mail. We will support you for advisory opinion in purchasing, explanation in various technical problems and reliable supply in technique support.

Services on Purchasing

- Communication by email.

- Welcome you visiting our factory and final users in China.

- Help for VISA application and Invitation Letter issuing.

Services after Sales

- Online Support, 24 hours feedback once got the email

- Enough Spare Parts Preparation for you…

- Engineer to customer’s site for training & repairment

- Our equipments have 12 months for quality guarantee after sale. If the equipments do not work because of self cause, we will do free service and change the damaged spare parts.

- We will do life-long maintenance for all of our sold equipments. After quality guarantee period, if you can not maintain the equipments by self, we are under an obligation to go to work place and assist you to make maintenance. The cost of spare parts as well as expenses of traveling and man-hour of worker will be negotiated separately. Spare parts will be supported whether during guarantee period or not.

- After have finished maintenance, our service engineer will do training for the operators in plenty of time so that operators can be ensured to independently make operation, debugging and daily plant maintenance.

Still under construction. coming soon...