-

tel: +86 21 5299 9232

-

email: inquiry@rsid-solutions.com

OVERVIEW

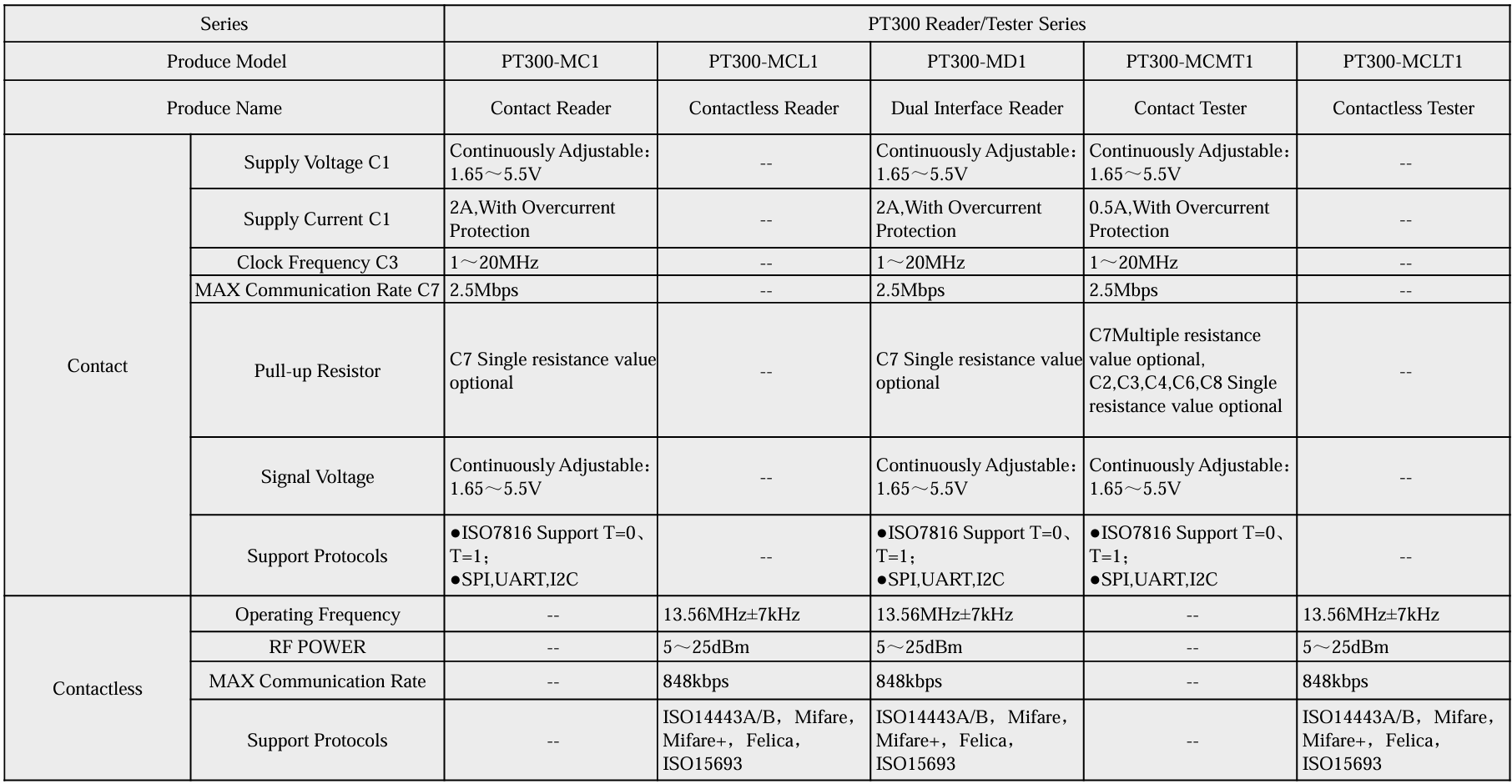

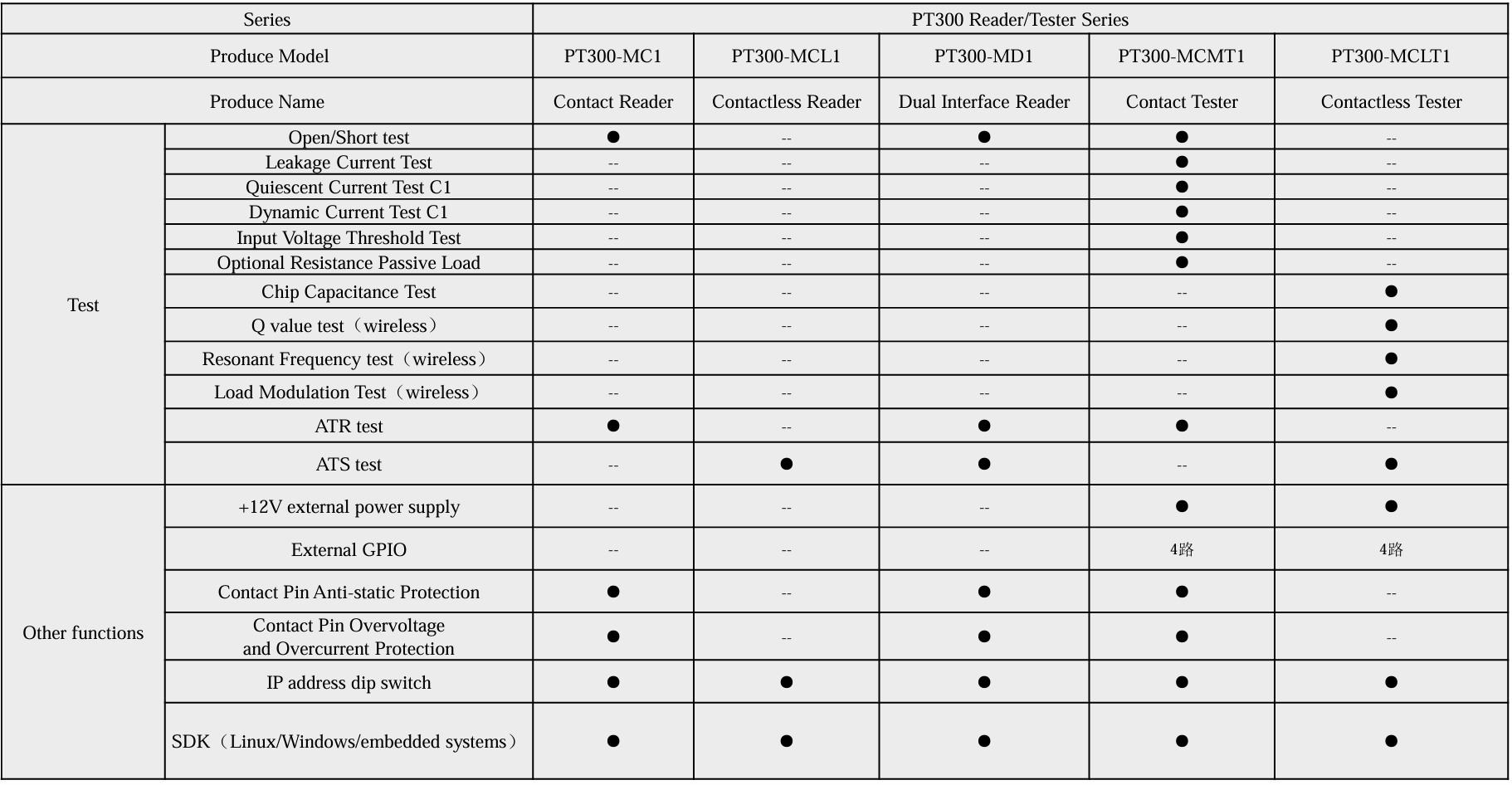

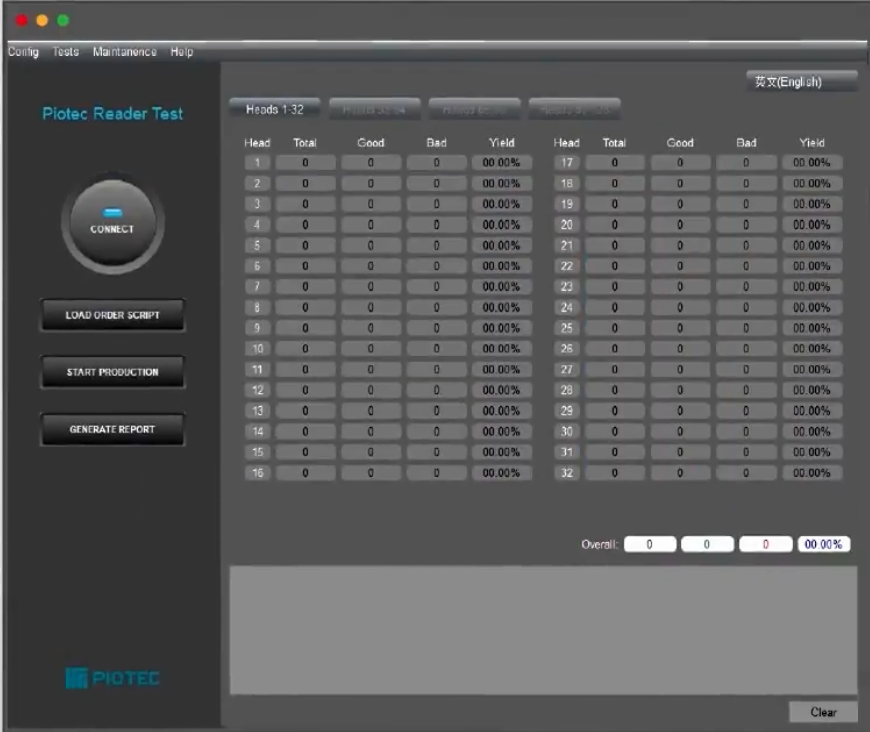

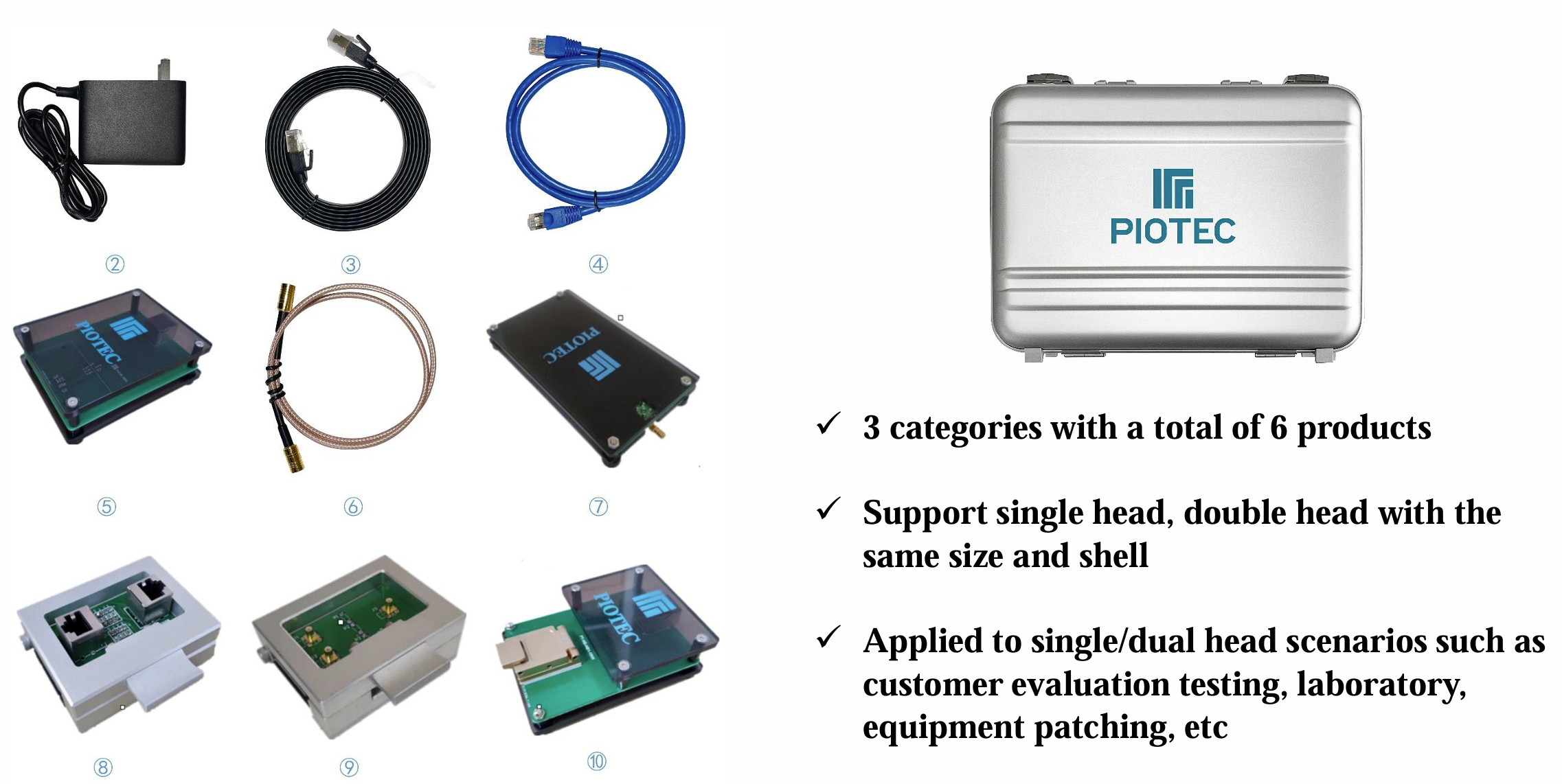

The PT300 series is a next-generation reader/writer platform designed for high-speed, multi-protocol testing in production and R&D environments. It supports contact, contactless, and dual-interface applications, integrating advanced features like parallel testing, FPGA acceleration, and extensive protocol compatibility. Key applications include smart card personalization, electrical performance testing, and IoT device manufacturing.

FEATURES

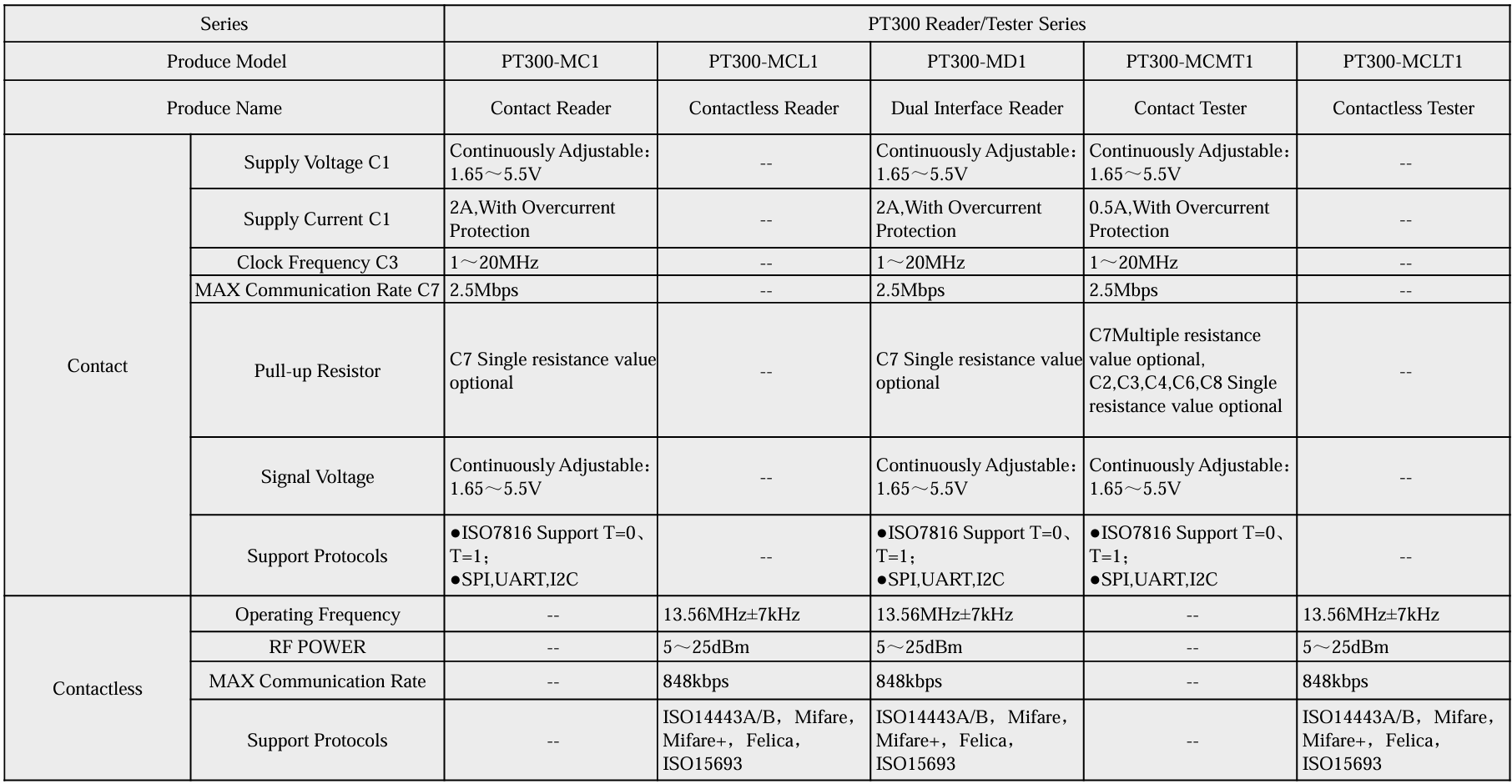

· Multi-Protocol Support: ISO7816, ISO14443A/B, MIFARE, FeliCa, ISO15693, NFC, and more.

· High-Speed Testing: 10x faster than predecessors (150ms per cycle).

· Modular Design: Scalable architecture with up to 80 channels (expandable via rack systems).

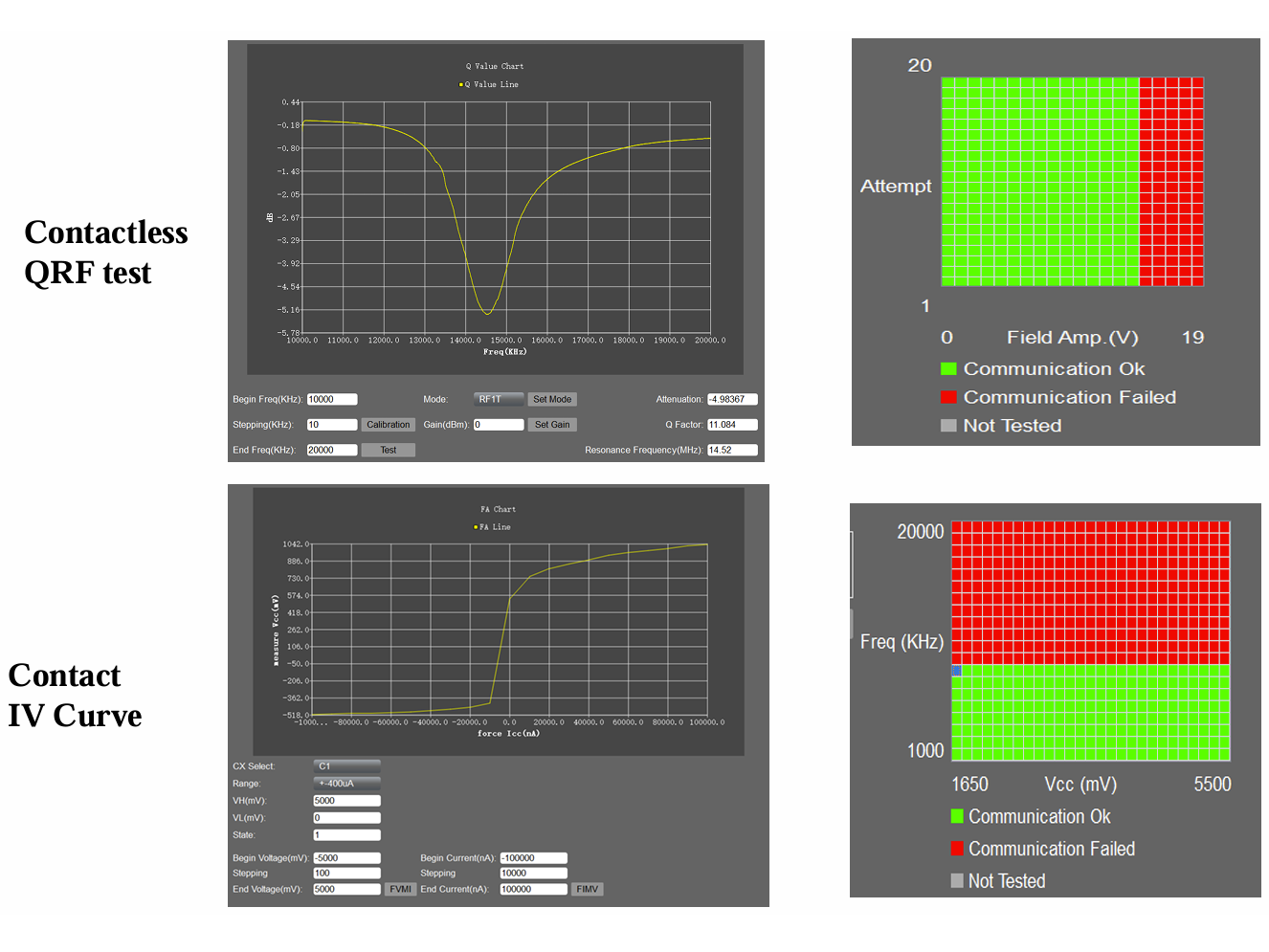

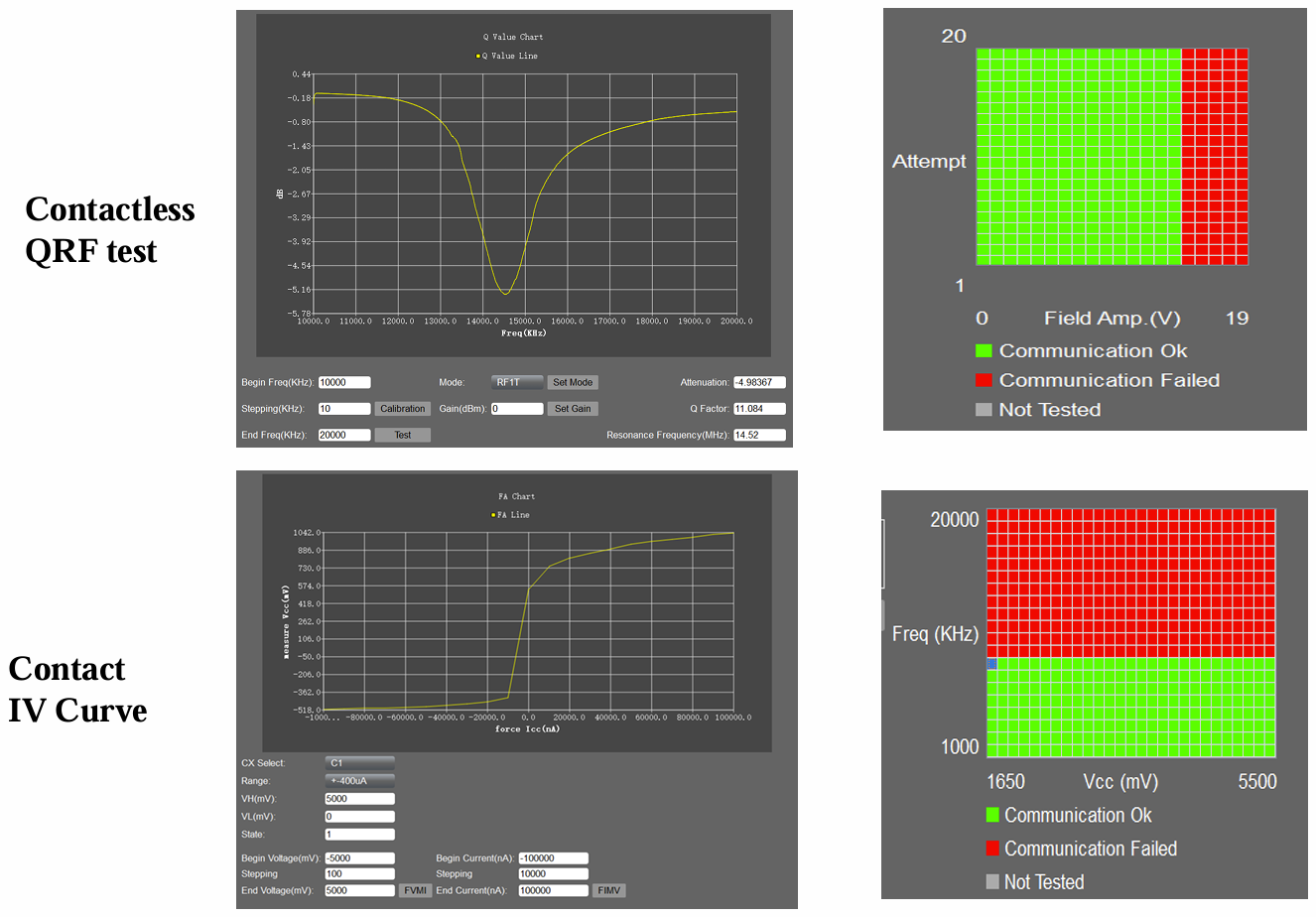

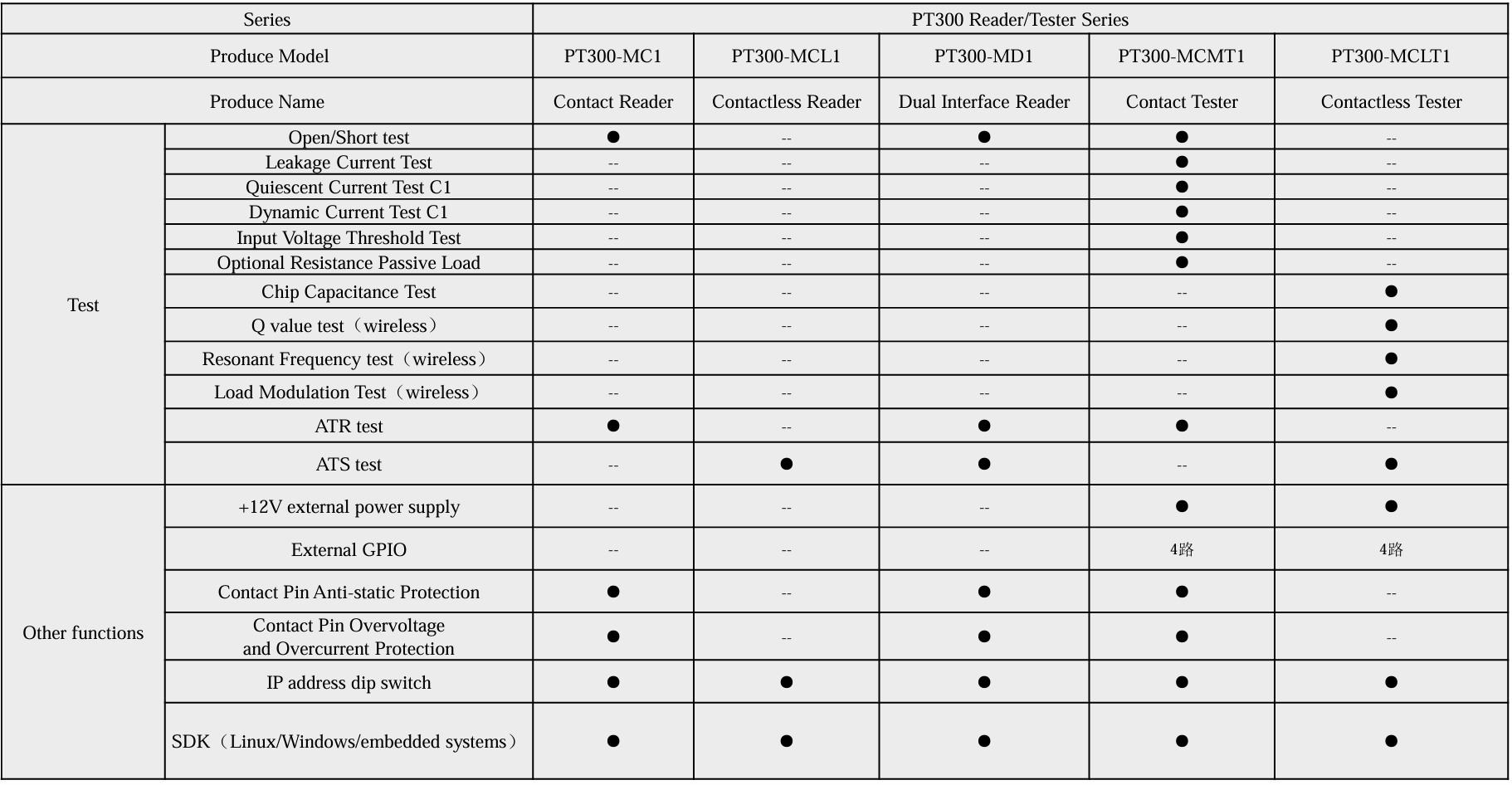

· Electrical Testing Capabilities: Contact testing (open/short, leakage current, dynamic ICC) and contactless testing (Q-factor, resonance frequency, load modulation).

· Adaptable to Various Materials: Contact cards, inlays, modules, and dual-interface chips.

· Precision Control: Adjustable voltage (1.65–5.5V), frequency (1–20MHz), and communication protocols.

· Integration-Friendly: Compatible with automation equipment (e.g., handlers) via digital I/O interfaces.

SPECIFICATIONS

Still under construction. coming soon...

· Multi-Protocol Support: ISO7816, ISO14443A/B, MIFARE, FeliCa, ISO15693, NFC, and more.

· High-Speed Testing: 10x faster than predecessors (150ms per cycle).

· Modular Design: Scalable architecture with up to 80 channels (expandable via rack systems).

· Electrical Testing Capabilities: Contact testing (open/short, leakage current, dynamic ICC) and contactless testing (Q-factor, resonance frequency, load modulation).

· Adaptable to Various Materials: Contact cards, inlays, modules, and dual-interface chips.

· Precision Control: Adjustable voltage (1.65–5.5V), frequency (1–20MHz), and communication protocols.

· Integration-Friendly: Compatible with automation equipment (e.g., handlers) via digital I/O interfaces.

· Superior Performance: 10× faster testing than PT200 , ideal for high-volume production.

· Comprehensive Testing: Combines contact (e.g., voltage/current) and contactless (e.g., QRF) capabilities in one platform.

· Flexibility: Modular design allows customization for specific applications (e.g., NFC tag validation, eSIM programming).

· Cost Efficiency: Lower total cost compared to standalone testers like SW/MP.

· Ease of Integration: Plug-and-play with existing automation systems (e.g., pick-and-place machines).

· Customer Testimonials: Positive feedback from customers in the smart card and RFID industries, highlighting the PT300 series' reliability, speed, and ease of use.

· Case Studies: Successful implementation in various production environments, including R&D laboratories and manufacturing facilities, demonstrating the product's versatility and effectiveness.

· Industry Recognition: Acknowledgment by industry experts and professionals for its innovative design and superior performance.

· Technical Support: 24/7 access via email, phone, or live chat.

· Training: Onsite workshops and webinars for new users.

· Maintenance: Warranty coverage and repair services for hardware/software issues.

· Updates: Firmware/software upgrades to ensure compatibility with emerging standards.

Q: Can PT300 replace SW for NFC antenna testing?

A: Yes, PT300 offers similar RF performance metrics (e.g., Q-factor, resonance frequency) with faster throughput.

Q: Does PT300 support scripting for automated testing?

A: Yes, via embedded Lua scripting (PRE programs) or integration with external control software.

Q: What’s the maximum number of channels supported?

A: Up to 80 channels with multiple expansion boards (e.g., 10 boards × 8 channels each).

Q: Is PT300 compatible with legacy PT200 accessories?

A: Partially compatible; newer rack systems and test heads are recommended for optimal performance.