-

tel: +86 21 5299 9232

-

email: inquiry@rsid-solutions.com

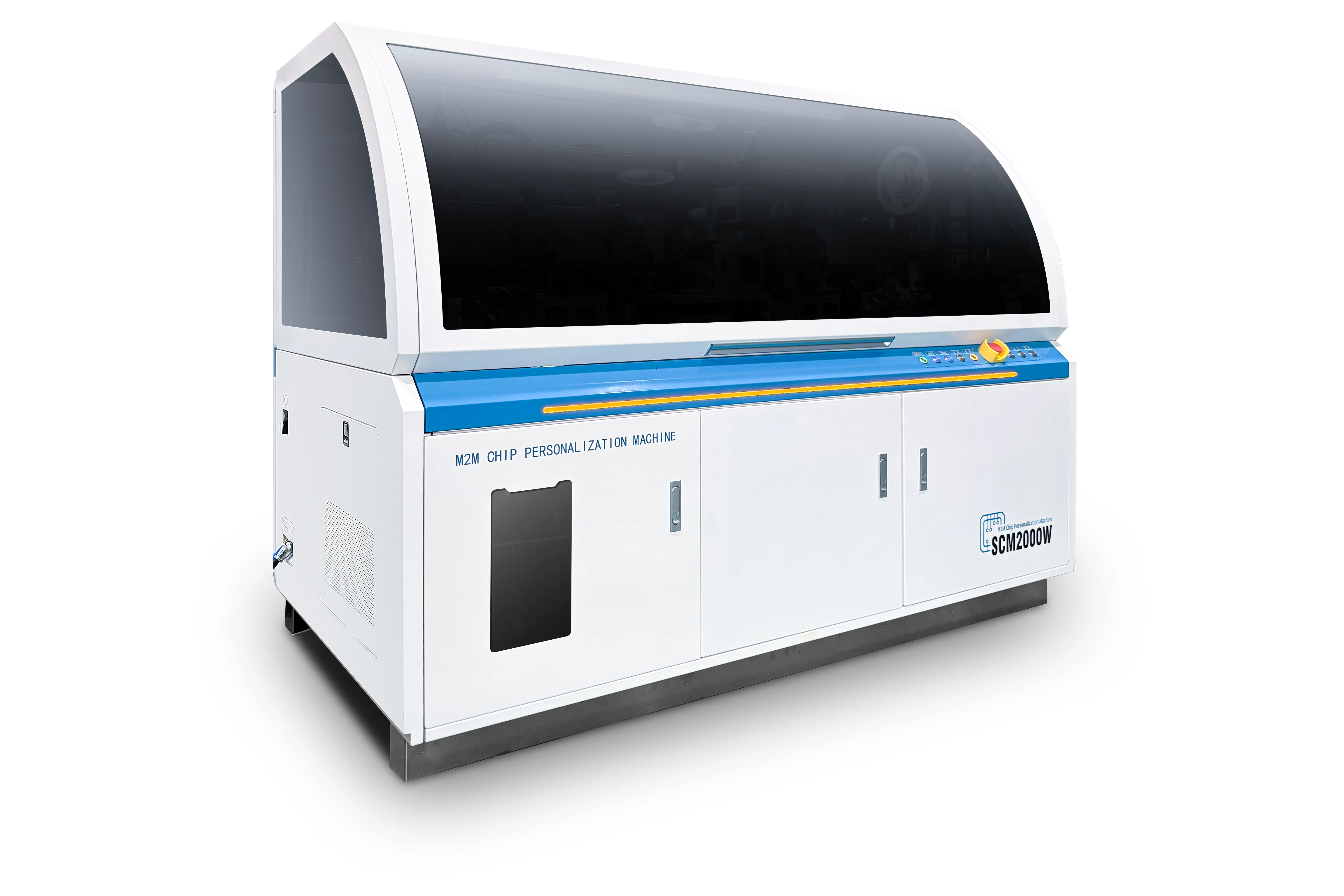

M2M Chip Personalization Machine SCM2000W

Presentation: Amazing & Innovative Design Auto Laminator

Advantage: Easy Operation, Durable 7x24 Concepts, Mature Tech

Application: Plastic/Smart Card, Pre-laminated Inlay Manufacturer

OVERVIEW

The ultra-small WLCSP chip is the main personalized production object, and can be compatible with chips of various packaging forms such as QFN and DFN.

WORK FLOW & APPLICATIONS

ADVANTAGES

· High Compatibility

1) The minimum support 2mm X 2mm (LxW) chip high-speed personalized production;

2) The ultra-small WLCSP chip is the main personalized production object, and can be compatible with chips of various packaging forms such as QFN and DFN.

· High Capacity

1) For 2mm x 2mm WLCSP chips, the maximum production capacity of the device can reach 2,500UPH.

2) The IC encoding mechanism is configured with 32 encoding stations and readers and the personalization time is less than 46 seconds, the device capacity can always be maintained at 2,500UPH.

· Effectively Prevent Chip Damage

The pressure detection function designed for "thin, brittle and small" WLCSP chip can effectively prevent the chip from being damaged by excessive pressure during transferring.

· Quick Change Kit

1) High order exchange efficiency: chip order switching of different package specifications can be completed within 1 hour;

2) The KIT replacement process is convenient and fast: the position of the mechanism is automatically calibrated through the visual system, and the physical position of the mechanism is not manually adjusted after the replacement of the KIT.

· High Performance Reader

The new generation PT300 series reader based on FPGA architecture is equipped with stronger performance and more stable work, supporting multi-protocol serial encoding, and can be extended to support the test of various contact electrical performance indicators such as open short circuit and leakage current.

· High Precision and High Stability

During the chip transfer process, the vision system collects the precise position of the chip and the target point in real time, and ensures the high accuracy and operation stability of the chip transfer through high-speed real-time displacement calculation.

· High Security

1) The chips are all placed inside the equipment, which is not easy to be touched at will, and the production process fully meets the requirements of various safety qualifications.

2) Multiple sets of vision systems are configured to monitor the entire process of chip transportation and the accuracy of data throughout. Moreover, the sequence of chips is detected by the visual system before and after taping to ensure data security during the production process.

· Effective Laser Dust Removal

The chip is laser etched in a closed area to effectively absorb laser dust.

CONFIGURATIONS & FUNCTIONS

Feeder Input Module

· The tape width supports 8mm & 12mm, and the material tray diameter supports 7 "& 13".

· The tape after inputting can be automatically crushed and recycling.

Manipulator Module

· Contains 4 sets of manipulators, each set of mechanical hands contains 4 degrees of freedom (XYZR axes), to realize the position correction during the chip transfer process, to ensure the stability of the micro chip in the high-speed transfer process;

· It has a pressure control function to ensure that the chip is not crushed;

· Equipped with 4 sets of nozzle, compatible with a variety of chip specifications, to achieve high-speed chip transfer;

· With the chip steering function, the chip direction can be adjusted.

IC Encoding Module

· Equipped with 32 encoding stations and readers to support multi-protocol data encoding and conventional electrical

performance detection;

· Two sets of switch clamping mechanisms are configured to realize the synchronization of chip transfer and encoding.

Laser Marking Module

· Equipped with 1 20W optical fiber marking machine, 1 smoke purifier;

· Configure 1 set of turntable module to realize synchronous chip transfer and laser marking;

· Equipped with a set of sealed structure for laser dust removal to realize the function of isolating laser dust from external mechanism.

Vision Verification Module

· Configure multiple sets of visual positioning cameras for chip position detection during motion;

· Three sets of detection cameras are configured to realize the logic number sequence detection function before and after the hot stamping of the carrier tape.

IC Verification Module

· Configure 8 verification stations and readers;

· The configuration of the reader is the same as that of the "IC Encoding Module";

· Two sets of switch clamping mechanisms are configured to realize the synchronization of chip transfer and IC verification.

Tape output Module

· The tape width supports 8mm & 12mm, and the material tray diameter supports 7 "& 13";

· Configure the first inspection station to facilitate the offline inspection of finished materials by the operators.