-

tel: +86 21 5299 9232

-

email: inquiry@rsid-solutions.com

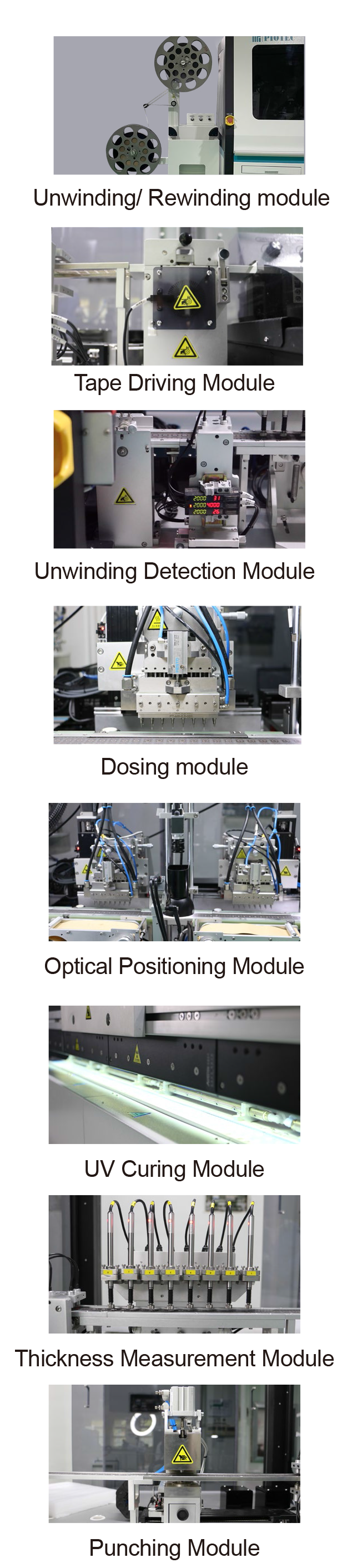

Chip Module Encapsulation Machine PTCME302

Presentation: The new generation of high-speed smart card chip module dosing, UV curing, encapsulated module thickness measurement and visual inspection system.

Advantage: Easy Operation, Durable 7x24 Concepts, Mature Tech

Application: Smart Card Chip Module Encapsulation

Throughput

SPECIFICATIONS

|

Dimension |

• 7300mm×1200mm×2000mm(LxWxH) |

|

Weight |

• 2100kg |

|

Power Supply |

• 220V (-5%~+10%), 50Hz, 8KW |

|

Noise |

• < 65 dB |

|

Operation Temperature |

• 23℃±3℃ |

|

Operation Humidity |

• 50±10%rh |

|

Compressed Air |

• Pressure: 0.6MPa Flow:1500LPM |

|

Maximum Throughput |

• Glob Top:33000UPH Damm & Fill:23000UPH |

|

Dimension |

• 7300mm×1200mm×2000mm(LxWxH) |

|

Weight |

• 2100kg |

|

Power Supply |

• 220V (-5%~+10%), 50Hz, 8KW |

|

Noise |

• < 65 dB |

|

Operation Temperature |

• 23℃±3℃ |

|

Operation Humidity |

• 50±10%rh |

|

Compressed Air |

• Pressure: 0.6MPa Flow:1500LPM |

|

Maximum Throughput |

• Glob Top:33000UPH Damm & Fill:23000UPH |

Services before Sales

- Reply your inquiry within 24 hours.

- Communication by email.

- Welcome you visiting our factory and final users in China.

- Help for VISA application and Invitation Letter issuing.

- We afford you consultation for 24 hours of 7 days in the process of sale and after service by phone or mail. We will support you for advisory opinion in purchasing, explanation in various technical problems and reliable supply in technique support.

Services on Purchasing

- Communication by email.

- Welcome you visiting our factory and final users in China.

- Help for VISA application and Invitation Letter issuing.

Services after Sales

- Online Support, 24 hours feedback once got the email

- Enough Spare Parts Preparation for you…

- Engineer to customer’s site for training & repairment

- Our equipments have 12 months for quality guarantee after sale. If the equipments do not work because of self cause, we will do free service and change the damaged spare parts.

- We will do life-long maintenance for all of our sold equipments. After quality guarantee period, if you can not maintain the equipments by self, we are under an obligation to go to work place and assist you to make maintenance. The cost of spare parts as well as expenses of traveling and man-hour of worker will be negotiated separately. Spare parts will be supported whether during guarantee period or not.

- After have finished maintenance, our service engineer will do training for the operators in plenty of time so that operators can be ensured to independently make operation, debugging and daily plant maintenance.